Bowling ball

USBC specifications include physical requirements for weight (≤16 pounds (7.3 kg)), diameter (8.500 inches (21.59 cm)—8.595 inches (21.83 cm)), surface hardness, surface roughness, hole drilling limitations (example: a single balance hole including the thumb hole for "two-handed" bowlers[3]), balance, plug limitations, and exterior markings (structural and commercial), as well as requirements for dynamic performance characteristics such as radius of gyration (RG; 2.46—2.80), RG differential (≤0.06), and coefficient of friction (≤0.32).

[2] Briefly, "soaker" ball technology—involving softening coverstocks to achieve greater hook—were used, until rules for minimum hardness were implemented.

[2][7][9] In the "particle-enhanced" balls developed in the late 1990s, microscopic particles embedded in reactive coverstocks reach through oil lane coatings to provide even greater traction.

[2][7] Ball manufacturers developed closely guarded proprietary blends including ground-up material such as glass, ceramic or rubber, to enhance friction.

[12][14] Bowling ball motion is influenced by how far the pin and the mass bias (MB) are from the PAP, the distances determining track flare.

[16] Many bowlers using the so-called "two-handed delivery" (which is still a one-handed release) do not insert their thumbs, thus allowing their fingers to impart even more torque than the fingertip grip.

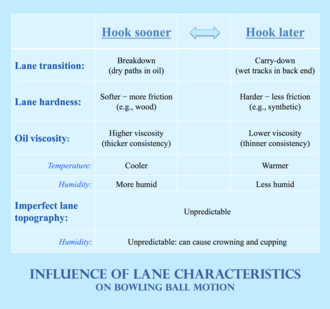

A complex interaction of a variety of factors influences ball motion and its effect on scoring results.

Bowling ball motion[21] is commonly broken down into sequential skid, hook, and roll phases.

[27] This ratio continually decreases throughout the ball's travel until it reaches exactly 1.0 when full traction is achieved upon entering the roll phase.

[29] The following discussion considers delivery characteristics separately, with the understanding that ball motion is determined by a complex interaction of a variety of factors.

[31] Greater degrees of initial (at-the-foul-line) axis tilt cause the ball to rotate on smaller-circumference "tracks" (rings on the ball at which it contacts the lane on each revolution), thus reducing the amount of frictional contact to provide greater length and less hook; conversely, smaller degrees of axis tilt involve larger-circumference tracks with more frictional contact per revolution, thus providing less length and more hook.

[32] Freeman and Hatfield (2018) explain that in most circumstances it is chemical friction—controlled by the manufacturer's proprietary coverstock formulation governing its "stickiness"—that primarily determines ball motion.

[26] Though manufacturer literature often specifies track flare—exhibited by successive tracks of oil in a "bowtie" pattern and caused by RG differential—the USBC ball motion study showed flare's influence to be small,[32] assuming that a minimal threshold of flare exists to present a "dry" surface for successive ball revolutions.

[33][9] Analytically, the United States Bowling Congress defines RG as "the distance from the axis of rotation at which the total mass of a body might be concentrated without changing its moment of inertia".

[33] Conversely, a lower RG indicates the ball's mass is distributed more towards its center—making it "center heavy"—which tends to make it enter the roll phase sooner.

[45][49] The process of oil removal, commonly called breakdown, forms dry paths that subsequently cause balls to experience increased friction and to hook sooner.

[45] Also, high humidity increases friction that reduces skid distance so the ball tends to hook sooner.

[51] Duckpin balls are sometimes used for scaled-down ten-pin bowling lanes installed in arcades and other amusement facilities.

[citation needed] There are also special balls for novice players, which is 14 cm (5.5 in) in diameter and weigh 1.9 kg (4.2 lb), often with two finger holes.