Constant-velocity joint

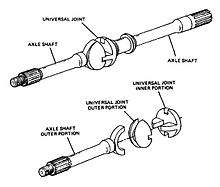

A common use of CV joints is in front-wheel drive vehicles, where they are used to transfer the engine's power to the wheels, even as the angle of the driveshaft varies due to the operation of the suspension.

DCJs are typically used in steering columns, as they eliminate the need to correctly phase the universal joints at the ends of the intermediate shaft (IS), which eases packaging of the IS around the other components in the engine bay of the car.

They are also used to replace Rzeppa style constant-velocity joints in applications where high articulation angles, or impulsive torque loads are common, such as the driveshafts and halfshafts of rugged four-wheel drive vehicles.

To be truly constant-velocity, Double Cardan joints require a centering element that will maintain equal angles between the driven and driving shafts.

When the input and output shafts are inclined at some working angle to each other, the driving intermediate member accelerates and decelerates during each revolution.

Since the central tongue and groove joint are a quarter of a revolution out of phase with the yoke jaws, the corresponding speed fluctuation of the driven intermediate and output jaw members exactly counteracts and neutralizes the speed variation of the input half member.

Thus the output speed change is identical to that of the input drive, providing constant velocity rotation.

The input shaft fits in the centre of a large, steel, star-shaped "gear" that nests inside a circular cage.

Two balls in circular tracks transmit the torque while the other two preload the joint and ensure there is no backlash when the direction of loading changes.

This action fulfills the requirement that the balls lie in the plane that bisects the angle of drive.

[15] Modifying the input and output yokes so that they are not precisely normal to their respective shafts can alter or eliminate the "disallowed" angles.

[18][19] The CV joints allowed a smooth transfer of power over a wider range of operating angles (such as when the suspension is compressed by cornering force or a bump in the road).

Modern rear-wheel drive cars with independent rear suspension typically use CV joints at the ends of the half-shafts and increasingly use them on the tailshaft.

[citation needed] A separate flexible cover is usually installed over the CV joint, to protect it from foreign particles and prevent the lubricating grease from leaking out.

Cracks and splits in the boot will allow contaminants in, which would cause the joint to wear quickly or completely fail.

An all-metal universal joint or CV located inside and protect by a solid axle (housing), swivel hub or closed knuckle may be desirable in harsh operating environments, where rubber is prone to physical or chemical damage.