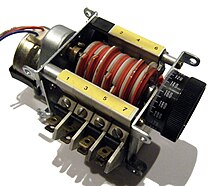

Cam timer

An electric motor drives a shaft arranged with a series of cams or a drum studded with pegs along its surface.

Most cam timers use a miniature mains synchronous motor to rotate the mechanism at an accurate constant speed.

The most basic cam timer rotates continually, which is inconvenient when waiting for events that occur at variable times.

Some cam timers also have a fast forward mode, where applying power to a point on the controller causes rapid advance of the mechanism.

Using feedback, external time delay, and other sensory circuits, it is possible to build an electromechanical state machine using a cam timer.

Electronic controllers have largely replaced cam timers in most applications, primarily to reduce costs and also to maximize product features.

Cam timers don't offer the greater flexibility that CPU-based controllers provide.

In addition to offering more wash program variations, a CPU-based washing machine controller can respond to malfunctions, automatically initiate test cycles, reducing manufacturing costs, and provide fault codes in the field, again reducing repair costs.