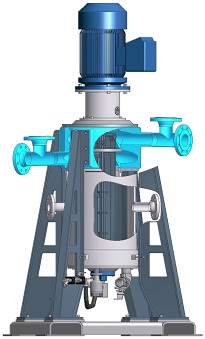

Centrifugal extractor

[1][2] The first liquid-liquid centrifugal contactor was invented by Walter Podbielniak[3] with the patent filed in 1932, then a series of developed models which were and continue to be used for whole variety of processes including solvent extraction of minerals and the purification of vegetable oils, but notably for the production of penicillin in World War II.

[6] Two immiscible liquids of different densities are fed to the separate inlets and are rapidly mixed in the annular space between the spinning rotor and stationary housing.

The mixed phases are rapidly accelerated to rotor speed and separation begins as the liquids are displaced upward.

Annular centrifugal contactors are relatively low revolutions-per-minute (rpm), moderate gravity enhancing (100–2000 G) machines, and can therefore be powered by a direct drive, variable speed motor.

The effectiveness of a centrifugal separation can be easily described as proportional to the product of the force exerted in multiples of gravity (g) and the residence time in seconds or g-seconds.

), and an immiscible solvent having a different density (light phase on cross section sketches) flow counter-currently through the extractor’s rotor, designed with a stack of mechanical subassemblies representing the required number of separate stages.

As described above, the mix & separation configuration is the standard operation for centrifugal contactors used for liquid-liquid extraction processes.

Inside the rotor, the liquids will be separated into a heavy (blue) and a light (yellow) phase by their respective densities.