Masonry heater

Archaeological digs have revealed excavations of ancient inhabitants utilizing hot smoke from fires in their subterranean dwellings, to radiate into the living spaces.

In particular, a masonry heater is designed specifically to capture and store a substantial portion of the heat from a solid fuel fire in the mass of the masonry heater through internal heat-exchange flue channels, to enable a charge of solid fuel (mixed with an adequate amount of air) to burn rapidly and more completely at high temperatures, in order to reduce emission of unburned hydrocarbons, and be constructed of sufficient mass and surface area such that under normal operating conditions, the external surface temperature of the masonry heater (except in the region immediately surrounding the fuel loading door(s)) does not exceed 110 °C (230 °F).

Seating and even beds can be built adjoining the masonry stove; this is possible because the heater's exterior surfaces are cool enough to touch safely.

The characteristic of slow heat-release can make a masonry heater a more convenient option for heating a house than a metal wood stove.

[2]: 172 The speed with which a stove, masonry or otherwise, achieves the right temperature is determined by the specific thickness and characteristics of the materials used in its construction.

Such stoves were carefully designed so that the minimum amount of heat would escape, only as much as needed to warm the flue to maintain a proper air draught.

[3]: 100 The Russian stove, another typical masonry heater, evolved in Russia in 15th century, after the brick flue was added to the traditional black-fired fireplace, which lacked the smokestack and vented directly into the room.

The typical Russian stove is a large, generally cuboid mass of masonry, usually weighing around 1–2 tons, built in the center of a traditional izba log hut, covered in stucco and carefully whitewashed.

[citation needed] Most Russian stoves consist of a massive firebrick hearth, often large enough for a grown man to fit into, with a flue continuing into a maze-like heat exchanger built of a normal brick, usually with a built-in stove for cooking, which sometimes used a secondary fireplace to quickly cook foods without heating the whole affair; all covered with an outer brick shell, normally with a pedestal for a kitchen work and beds built into it.

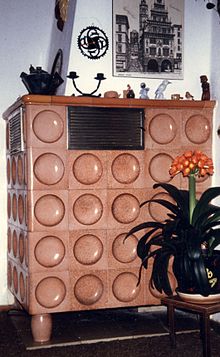

Traditional Finnish stoves closely follow the round Swedish tile heater in appearance, typically constructed from brick.

Since masonry heaters burn hot and fast, they can accept any dry, split wood, usually three to five inches (8 to 13 cm) in diameter.

The electric heating is required to prevent the building from freezing damage should it be left unattended for long periods during the winter.

As in the past, once the firewood has burned, the warmed mass of the stove continues to radiate heat, but the sizes of the flue passages of modern masonry heaters are more exactly calculated to provide increased efficiency and output and use less wood.