Collaborative product development

[citation needed] Collaborative Product Development helps individual users and companies manage, share and view your CAD projects without the cost and complexity of purchasing an entire PDM or PLM solution.

Exactly what techniques and technology is required depends on the level of collaboration being carried out and the commonality (or lack thereof) of the partner sites’ systems.

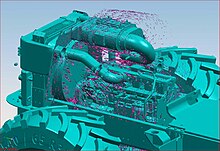

Improved visualization capabilities, especially those that provide a meaningful view of complex information such as the results of a fluid flow analysis will leverage the value of all participants in the collaboration process.

Effective collaboration requires that a participant be freed from the burden of knowing the intent history typically imbedded within and constricting the use of parametric models.

Models from multiple CAD sources must be assembled into an active digital mockup allowing change and/or design in context.

A neutral modeling commands (NMC) based method is proposed to construct a real-time collaborative product design platform within heterogeneous CAD systems.

If the collaborating parties have the same PDM and CAD systems the task usually involves the direct access and transfer of data between sites.

For the translation process Product Data Quality (PDQ) checkers are often employed to reduce problems in transferring the work.