Compact fluorescent lamp

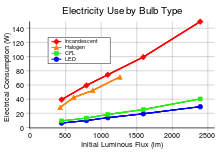

Compared to general-service incandescent lamps giving the same amount of visible light, CFLs use one-fifth to one-third the electric power, and last eight to fifteen times longer.

This was the first successful screw-in replacement for an incandescent lamp, using new rare earth aluminum lattice phosphors to solve the problem of lumen depreciation that would normally occur quickly in such a thin tube; however, it was not widely adopted, because of its large size, weight (over half a kilogram), pronounced 50 Hz flicker and 3-minute warm up time.

[19] In the United States, CFLs were also facing the possibility of proposed regulations for 2017 that would create difficulty qualifying for the Energy Star rating.

[19][5] On September 1, 2021, the EU banned the export, import, manufacture and sale of all compact fluorescent lamps with integrated ballasts.

Since the ballasts are placed in the light fixture, they are larger and last longer compared to the integrated ones, and they do not need to be replaced when the tube reaches its end-of-life.

A bi-pin tube contains an integrated starter, which obviates the need for external heating pins but causes incompatibility with electronic ballasts.

Since the resonant converter tends to stabilize lamp current (and light emitted) over a range of input voltages, standard CFLs respond poorly in dimming applications and will experience a shorter lifespan and sometimes catastrophic failure.

As a result material from the electrodes is ejected every time sputtering occurs and it is deposited on the fluorescent tube's walls, showing as lamp end darkening.

The US Energy Star program suggests that fluorescent lamps be left on when leaving a room for less than 15 minutes to mitigate this problem.

Exchanging ILs for efficient CFLs on a global scale would achieve annual CO2 reductions of 230 Mt (million tons), more than the combined yearly CO2 emissions of the Netherlands and Portugal.

A US article stated "A household that invested $90 in changing 30 fixtures to CFLs would save $440 to $1,500 over the five-year life of the bulbs, depending on your cost of electricity.

[49] According to an August 2009 newspaper report, some manufacturers claimed that CFLs could be used to replace higher-power incandescent lamps than justified by their light output.

[51] Equivalent wattage claims can be replaced by comparison of actual light output emitted by the lamp, which is measured in lumens and marked on the packaging.

[52] In addition to the wear-out failure modes common to all fluorescent lamps, the electronic ballast may fail, since it has a number of component parts.

[54] New North American technical standards aim to eliminate smoke or excess heat at the end of lamp life.

Cold-cathode CFLs can be dimmed to low levels, making them popular replacements for incandescent bulbs on dimmer circuits.

The power factor of CFLs does not significantly affect their energy-saving benefits for individual consumers, but their use in large numbers, such as in commercial applications or across millions of homes in a distribution system, could require infrastructure upgrades.

[71] Some CFLs are marketed as "instant on" and have no noticeable warm-up period,[72] but others can take up to a minute to reach full brightness,[73] or longer in very cold temperatures.

The light emitted by some single-envelope CFLs at distances of less than 20 cm (7.9 in) could lead to ultraviolet exposures approaching the current workplace limit set to protect workers from skin and retinal damage.

At closer distances, comparisons show that CFLs emit less UVA (long wavelength) radiation than incandescent light bulbs.

Closed (double-envelope) CFLs are shielded and emit a lower total UV radiation compared to incandescent or halogen bulbs of a similar wattage.

For those with skin sensitivity long term indoor exposure may be a concern, in which case they may want to use a bulb with lower UV radiation output.

Spectroscopic analysis confirmed the presence of significant UVA and UVC radiation, which the study's authors conjectured was attributable to damage in the bulbs' internal phosphor coatings.

The study's authors suggest that the ultraviolet exposure could be limited by the use of "double-walled" bulbs manufactured with an additional glass covering surrounding the phosphor-coated layer.

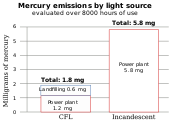

In areas where electric power is mostly generated in coal-fired stations, replacing incandescent bulbs by CFLs actually reduces mercury emissions.

[88] The U.S. Environmental Protection Agency (EPA) has published best practices for cleanup of broken CFLs, and ways to avoid breakage, on its web site.

[91] Health and environmental concerns about mercury have prompted many jurisdictions to require spent lamps to be properly disposed of or recycled, rather than being included in the general waste stream sent to landfills.

[92] Several states, including Vermont, New Hampshire, California, Minnesota, New York, Maine, Connecticut and Rhode Island, have regulations that are more stringent than the federal UWR.

[94] The first step of processing CFLs involves crushing the bulbs in a machine that uses negative pressure ventilation and a mercury-absorbing filter or cold trap to contain mercury vapor.

In the United States and Canada, the Energy Star program labels lamps that meet a set of standards for efficiency, starting time, life expectancy, color, and consistency of performance.

• Compact Fluorescent (General Electric, 13 W, 6500 K)

• Incandescent (Sylvania, 60 W, Extra Soft White)

• Compact Fluorescent (Bright Effects, 15 W, 2644 K

• Compact Fluorescent (Sylvania, 14 W, 3000 K)