Composite repair

The bonded composite repair reduces stresses in the damaged region and prevents cracks from opening or growing.

Composite materials are used in a wide range of applications in aerospace, marine, automotive, surface transport and sports equipment markets.

Laminate structures are assembled so that the fibre orientation provides most of the desired mechanical properties and the matrix largely determines the environmental performance.

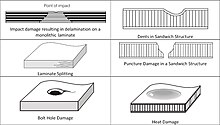

In monolithic laminates the underlying damage can extend to a much greater extent than the barely visible evidence on its surface.

In sandwich structures, impact results in dents of various sizes and depending on the energy levels, puncture damage is not unusual.

Any alternative would need careful consideration of the service environment of the repaired composite, i.e. hot, wet and mechanical performance.

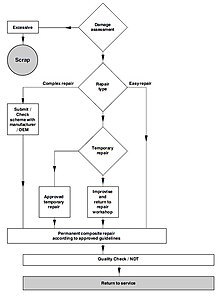

A typical composite repair usually starts after damage detection either by unaided eye or various other NDT-techniques.

This is why current developments tend to focus on automating this process either by advanced mechanical milling or alternate technologies like nanosecond-pulsed lasers 2-3.

After the damage zone has been completely excavated, surfaces are cleaned and further prepared for the final repair by patches.

In a typical repair, the patch is applied under vacuum and at temperatures high enough for the curing of the adhesive.

Vacuum bag processing is suited to components with thin sections and large sandwich structures.

This can be achieved by using heating mat or by placing the assembly inside an oven with good air circulation.

For thicker sections and high quality bonding, the use of an autoclave with regulated temperature and additional overpressure should be sought.