Compressed air dryer

As the compressed air cools down, water vapor condenses into the tank(s), pipes, hoses and tools connected downstream from the compressor which may be damaging.

[citation needed] Next to these damage mechanisms, in outdoor situations, water can accumulate and then freeze, leading to failure of components, e.g. braking systems.

Their performance characteristics are typically defined by flow rate in standard cubic feet per minute (SCFM) and dew point expressed as a temperature.

In principle, a coalescing filter is an ideal way to separate water from the compressed air stream.

Coalescing elements are extremely sensitive to oil and particulate contamination and therefore would be better placed as a second stage dryer.

However, the dew point performance of a coalescing filter places it in the primary category of compressed air dryers.

The way that dental compressors are designed and used makes a two-stage coalescing filter an almost ideal solution for water contamination in these systems.

When selected with the optional "cold coalescing filter", these units can deliver compressed air with lower dew points.

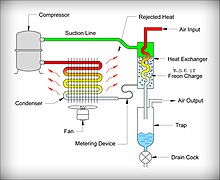

Freon-based refrigerated compressed air dryers generally consist of a heat exchanger that is similar to a water cooled after cooler.

The liquid is reintroduced into the heat exchanger via the metering device and a closed refrigeration cycle is formed.

As the compressed air is cooled, it loses its ability to retain moisture and the water vapor condenses onto the inside of the exchanger tube.

Variations on this basic design include units equipped with reheating exchangers, which are intended to improve efficiency.

Oil and water vapors in compressed air must have cooled to their dew point (become aerosols) before the coalescing filter can operate effectively.

[11] High temperature dryers are equipped with an additional pre-cooler that removes excess heat via a forced air system.

Compressed air temperatures in excess of 38 °C (100 °F) are very common in Southern climates, mining operations, steel mills, shipboard, etc.

JT type dryers are units that utilize the compressed air stream as their refrigeration element.

As the air expands to a lower pressure, it becomes cold (based on the Joule-Thomson Effect) and its ability to retain moisture is reduced.

The micro-droplets of water that make up the fog wet to the porous material and collect until they form droplets that can be affected by gravity.

Deliquescent dryers typically consist of a pressure vessel filled with a hygroscopic medium that has a high affinity for water vapor.

Practically speaking, these dryers are typically a large pressure vessel that is filled with salt crystals.

As liquid water builds on the salt crystals, brine is formed, which drains down and collects in the bottom of the vessel.

Desiccant dryers are typically supplied in two patterns, “Single Canister” and “Twin Tower” units.

When applied as a second stage dryer, they can easily and reliably produce dew points in the sub-zero range.

These types of filters provide the same basic function as a desiccant dryer except they use an ordinary roll of toilet paper as their absorption media.

The compressed air is passed through a pressure vessel with two "towers" filled with a media such as activated alumina, silica gel, molecular sieve or other desiccant material.

Oftentimes this will save significant amounts of energy which is one of the largest factors when determining the proper compressed air system.

A dry cover gas is flowed across the low pressure side and absorbs the water on the membrane.

This lowering of the outlet dew point is due to the longer residence time that the air has inside the membrane.

If set up and operated properly, membrane dryers can produce extremely low dew points.

For this reason they are very common in laboratories, medical facilities and specialty manufacturing environments where limited amounts of high quality compressed air is required.