Conveyor system

They also have popular consumer applications, as they are often found in supermarkets and airports, constituting the final leg of item/ bag delivery to customers.

Chain conveyors consist of enclosed tracks, I-Beam, towline, power & free, and hand pushed trolleys.

Conveyor systems are commonly used in many industries, including the Mining, automotive, agricultural, computer, electronic, food processing, aerospace, pharmaceutical, chemical, bottling and canning, print finishing and packaging.

Some individual areas that are helpful to consider are the required conveyor operations, such as transport, accumulation and sorting, the material sizes, weights and shapes and where the loading and pickup points need to be.

A conveyor system is often the lifeline to a company's ability to effectively move its product in a timely fashion.

The steps that a company can take to ensure that it performs at peak capacity, include regular inspections and system audits, close monitoring of motors and reducers, keeping key parts in stock, and proper training of personnel.

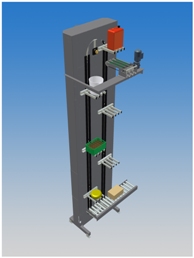

Overhead conveyor systems have been used in numerous applications from shop displays, assembly lines to paint finishing plants and more.

Conveyor systems require materials suited to the displacement of heavy loads and the wear-resistance to hold-up over time without seizing due to deformation.

As far as growth is concerned the material handling and conveyor system makers are getting utmost exposure in the industries like automotive, pharmaceutical, packaging and different production plants.

Every pneumatic system uses pipes or ducts called transport lines that carry a mixture of materials and a stream of air.

Three systems used to generate high-velocity air stream: A vibrating conveyor is a machine with a solid conveying surface which is turned up on the side to form a trough.

They are used extensively in food-grade applications to convey dry bulk solids[1] where sanitation, washdown, and low maintenance are essential.

Due to the fixed nature of the conveying pans vibrating conveyors can also perform tasks such as sorting, screening, classifying and orienting parts.

Vibrating conveyors have been built to convey material at angles exceeding 45° from horizontal using special pan shapes.

They are used in food packaging, case packing, and pharmaceutical industries and also in large retail stores such as Wal-Mart and Kmart.

Most spiral conveyors also have a lower angle of incline or decline (11 degrees or less) to prevent sliding and tumbling during operation.

The dual conveyors rotate in opposite directions, but are operated from one gear box to ensure equal belt speed.

A typical motorized roller conveyor zone can handle carton items weighing up to approximately 35 kg (75 lbs.).

Both cam and fluid power types require nests at each station to retain the part that is being moved.