Cromwell tank

The General Staff were aware that the Crusader would become obsolete, and in late 1940 they set out the specifications for a replacement tank, expected to enter service in 1942, fitted with the QF 6 pounder gun.

With engine power doubled, it soon became apparent that the additional stresses placed on the Crusader components required significant re-work to increase reliability.

BRC&W became parent to the Cromwell in September 1941 working with David-Brown (gearbox) RR (engine) and Leyland (tracks and sprockets) and produced a pilot in January 1942.

Things became particularly heated when Whittle learned that Rover had set up a secret project (with the approval of the Ministry of Aircraft Production) to develop a simpler-to-produce "straight-through" version of the W.2.

Whittle had, though Stanley Hooker of RR's supercharger division, been in contact with Rolls for help delivering some of the required parts that Rover proved unable to produce.

The Cromwell had - in line with the then General Staff policy - originally be armed primarily for anti-tank work and the current QF 6-pounder (a high velocity tank gun with armour piercing (AP) ammunition met the requirement.

The British experience in North Africa campaign was that during breakthroughs of the enemy line, tanks were encountered less but anti-tank guns and infantry were the main targets.

[dubious – discuss] At the same time, Cromwell with the Meteor engine and a HV weapon was shown to have superior power and armament, while US efforts to produce the Sherman replacement, the T20 medium tank, were not receiving sufficient attention.

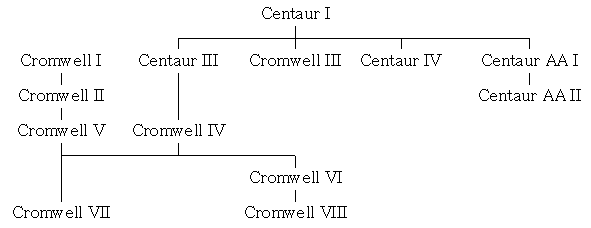

Centaur production bore the brunt of this reduction, having only been continued to maintain factories producing Cromwell hulls while the number of Meteor engines was inadequate.

The Shermans proved to be the most reliable by far, requiring 420 hours of specialist fitter attention over a total distance travelled of 13,986 mi (22,508 km) with 199 defects.

Companies contracted to build the tanks included English Electric, Harland and Wolff, John Fowler & Co., LMS Railway, Metro-Cammell, Morris Motors and Ruston-Bucyrus.

However, British tankers had long complained about this weapon's lack of a useful high explosive (HE) round for attacking soft targets like trucks, anti-tank guns and infantry defences.

This led Vickers to begin development of a 75 mm weapon of 50 calibres in length, which would fire the same HE shell as the US gun, but with a higher propellant load that would make its anti-tank rounds more effective.

[17] By comparison, the Cavalier can easily be identified by the vehicle's rear armour plate, which incorporates Crusader-style horizontal angled exhaust louvres.

For this reason, many Cromwell and Centaur vehicles had a cowl fitted to direct the exhaust gases back where they could not re-enter the tank fighting compartment.

[29] While successful, production ceased in favour of the much easier conversion of Sherman Fireflys, originally developed as a safeguard for the A30 programme,[29] allowing greater numbers to be fielded.

However, development of the Vickers HV 50 calibre 75 mm gun continued, with the bore increasing to fire modified versions of the 17-pounder ammunition.

By the time this weapon was ready, a number of other changes had been worked into the tank design, producing the Comet, which replaced both the Cromwell and Challenger.

The evolution to A27M increased the weight slightly, but fitting a 600 hp engine almost doubled the power-to-weight ratio and created a very fast tank.

This gave a significant reduction in armour penetration compared to newer 6-pounder armour-piercing discarding sabot ammunition, which was becoming available, but added the ability to fire high explosive (HE) shells, which were more capable against other targets, such as anti-tank guns.

The high velocity 75 mm gun was developed in an attempt to give both good anti-tank and HE performance, but in May 1943 proved too big to be fitted to the Cromwell.

This issue led to the development of the A34 Comet, while the gun bore was increased to 76.2 mm to become compatible with 17-pounder ammunition, albeit with smaller shell casings with less propellant.

The Cromwell's speed and low profile gave an advantage over the Sherman, however, giving the tank the element of surprise and making return fire more difficult.

Cromwell crews in north-west Europe succeeded in outflanking the heavier and more sluggish German tanks with superior speed, manoeuvrability and reliability.

The issue with the 75 mm gun was perhaps most pronounced during the Battle of Villers-Bocage in which the Cromwells were unable to engage German Tiger tanks frontally with any reasonable chance of success.

Originally intended to be used from landing craft[33] and serve as static pillboxes, these examples retained the engines, allowing the marines to drive the tanks inland.

[37] In December 1950, 14 tanks were organized into "Cooper Force", led by Captain Donald Ashley-Cooper, and were deployed to Jangheung, Yangju to support the 1st Battalion, Royal Ulster Rifles Regiment, whose duty was to defend northwest of Seoul.

On the night of 3 January 1951, the 1st Battalion of the Royal Ulster Rifles and Cooper Force retreated under orders from superior command to withdraw.

[37] One of the captured Cromwells operated by the Communist Party was destroyed by a British Centurion tank near Hangang Railway Bridge on February 1.

[46] The majority of following British tank designs utilised the Meteor engine and Merritt-Brown steering and gearbox combination initially developed for the Cromwell, lasting all the way through the Centurion.