Denby Pottery Company

Bourne later took over the Codnor Park and Shipley Potteries, and merged them into the Denby works in a similar manner.

Using a new patent process for drying slip invented by Needham and Kite of Vauxhall, the pottery produced at least 25 tons of workable clay each day.

[3] By the 1870s the pottery was producing a wide range of utilitarian stoneware products including telegraph insulators, ink bottles, pickle and marmalade jars, spirit and liquor bottles, foot warmers, churns, mortars and pestles, pipkins, feeding-bottles, pork pie moulds, druggists' shop-jars, snuff-jars, spirit-barrels, pudding-moulds, and water filters.

[4] The company benefited greatly from its transport links into Derby and beyond, particularly when the Midland Railway opened its Ripley Branch.

Each week around three or four vans would be dispatched to Chaddesden sidings (near Derby station) where they would be connected to an express to St Pancras in London and the company's warehouse at the Granary.

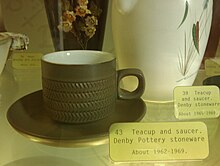

[5] The company, whose name is now principally associated with stoneware, initially produced bottles and jars, before specialising in kitchenware and, eventually, in tableware, for which it is best known today.

The venture into a new material saw Denby repurpose part of its existing factory, with additional staff taken on to produce the new lines.