Diving bell

A diving bell is a rigid chamber used to transport divers from the surface to depth and back in open water, usually for the purpose of performing underwater work.

Unlike a submersible, the diving bell is not designed to move under the control of its occupants, or to operate independently of its launch and recovery system.

The wet bell is a structure with an airtight chamber which is open to the water at the bottom, that is lowered underwater to operate as a base or a means of transport for a small number of divers.

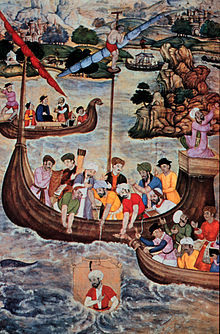

[5] In 1535, Guglielmo de Lorena created and tested his own diving bell to explore a sunken vessel in a lake near Rome.

[7][8] In 1642, John Winthrop reported one Edward Bendall building two large wooden barrels, weighted with lead and open at their bottoms, to salvage a ship Mary Rose which had exploded and sunk, blocking the harbor of Charlestown, Boston.

In late 1686, Sir William Phipps convinced investors to fund an expedition to what is now Haiti and the Dominican Republic to find sunken treasure, despite the location of the shipwreck being based entirely on rumor and speculation.

In January 1687, Phipps found the wreck of the Spanish galleon Nuestra Señora de la Concepción off the coast of Santo Domingo.

[11] In 1689, Denis Papin suggested that the pressure and fresh air inside a diving bell could be maintained by a force pump or bellows.

[7][12] In 1691, Dr. Edmond Halley completed plans for a diving bell capable of remaining submerged for extended periods of time, and fitted with a window for the purpose of undersea exploration.

[13] In 1775, Charles Spalding, an Edinburgh confectioner, improved on Halley's design by adding a system of balance-weights to ease the raising and lowering of the bell, along with a series of ropes for signaling the surface crew.

A fairly heavy ballast is often required to counteract the buoyancy of the airspace, and this is usually set low at the bottom of the bell, which helps with stability.

Abandonment of a type 2 wet bell requires the divers to manage their own umbilicals as they ascend along a remaining connection to the surface.

The bell with divers on board is deployed from the working platform (usually a vessel) by a crane, davit, or other mechanism with a man-rated winch.

The bell is lowered into the water and to the working depth at a rate recommended by the decompression schedule, and which allows the divers to equalize comfortably.

If the divers are breathing from the bell airspace at the time, it may need to be vented with additional air to maintain a low carbon dioxide level.

There may be an emergency through-water communications system with a battery power supply, and a location transponder working on the international standard 37.5 kHz.

[19][20] The bell may be fitted with an external emergency battery power pack, carbon dioxide scrubber for the internal atmosphere, and air conditioner for temperature control.

This will normally include a small tackle to lift the disabled diver into the bell through the bottom hatch and secure them in an upright position if needed.

The divers will also carry bailout gas in scuba cylinders, or as a semi-closed circuit rebreather, sufficient to get them back to the bellin the event of an umbilical supply failure.

This can be adjusted by tying off the umbilicals inside the bell to limit deployment length, which must often be done in any case, to prevent the divers from approaching known hazards in the water.

As the bell is lowered, the fairleads prevent it from rotating on the deployment cable, which would put twist into the umbilical and risk loops or snagging.

The system must constrain movement of the supported bell sufficiently to allow accurate location on the chamber trunking even in bad weather.

The diving bell would be connected via the mating flange of an airlock to the deck decompression chamber or saturation system for transfer under pressure of the occupants.

[25] The air lock diving-bell plant was a purpose-built barge for the laying, examination and repair of moorings for battleships[26] at Gibraltar harbour.

[29] In operation the barge would be towed over the work site, moored in place with anchors, and the bell would be lowered vertically to the bottom.

[29] The German service barge Carl Straat is similar in concept, but the bell is lowered by swinging the access tube.

Maximum working depth is 10 m. The vessel is used on those inland waterways which have locks large enough to accommodate its 52 m length overall, 11.8 m beam and 1.6 m draft.

A closed bell that has been depressurised for maintenance access will probably retain residual diving breathing gas mixture, which will usually be hypoxic at normal atmospheric pressure, and could cause anyone who enters to lose consciousness quite rapidly.

Helium based mixtures are buoyant and require active flushing with a strong flow of air, followed by testing for oxygen partial pressure before entry.

Since the spider must breathe air, it constructs from silk a habitat like an open diving bell which it attaches to an underwater plant.