Dounreay

Dounreay (/ˌduːnˈreɪ/;[2] Scottish Gaelic: Dùnrath) is a small settlement and the site of two large nuclear establishments on the north coast of Caithness in the Highland area of Scotland.

[3] The NRTE is to be decommissioned under a ten-year contract starting in 2023, ending in the creation of a brownfield site, which would be transferred to the NDA.

Visitors would be taken by bus to the PFR building where anything electronic, including watches and cameras, would be stored away securely until return.

Test pieces were encased in uranium-bearing alloy to increase the already high neutron flux of this class of reactor, and then chemically stripped of this coating after irradiation.

[11]: 74 The reactor was surrounded by a 139-foot (42 m) steel sphere, still a prominent feature of the landscape, which was constructed by the Motherwell Bridge Company.

The reactor core was initially fuelled with uranium metal fuel stabilised with molybdenum and clad in niobium.

[17] PFR was a pool-type fast breeder reactor, cooled by 1,500 tonnes[18] of liquid sodium and fuelled with MOX.

In the 1970s this plant was substantially modified and enlarged to enable it to reprocess mixed oxide fuel from the commercial scale Prototype Fast Reactor (PFR) on site, which had a design output of 250MW(e).

[22] Since the reactors have all been shut down,[7] care and maintenance of old plant and decommissioning activities have meant that Dounreay has still retained a large workforce.

[25] Following an incident in May 1998, where a mechanical digger cut through a main power cable and interrupted the site's main and back-up electricity supplies for 16 hours,[26] operations were halted in the Fuel Cycle Area (FCA) and a safety audit of the plant was undertaken by the UK Health and Safety Executive and the Scottish Environment Protection Agency.

[29] An accelerated decommissioning plan was welcomed by the Friends of the Earth Scotland, but the environmental group remained opposed to further fuel reprocessing at the site.

Following the 1998 report, the Department of Trade and Industry was presented with three options for dealing with 25 tonnes of radioactive reactor fuel at Dounreay.

The options were: A plan was eventually devised to remove irradiated and unirradiated fuel to the Sellafield nuclear site, starting in 2014.

[30] On 1 April 2005, the Nuclear Decommissioning Authority (NDA) became the owner of the site, with the UKAEA remaining as operator.

[31] A new company called Dounreay Site Restoration Limited (DSRL) was formed as a subsidiary of the United Kingdom Atomic Energy Authority (UKAEA) to handle the decommissioning process.

Removal of all waste from the site was expected to take until the late 2070s to complete, and the end-point of the project was scheduled for 2300.

[32] Apart from decommissioning the reactors, reprocessing plant, and associated facilities, there were five main environmental issues to be dealt with: Historically, much of Dounreay's nuclear waste management was poor.

On 18 September 2006, Norman Harrison, acting chief operating officer, predicted that more problems will be encountered from old practices at the site as the decommissioning effort continues.

[29] Due to the uranium and plutonium held at the site, it is considered a security risk and there is a high police presence.

[7] In 2013, the detail design of the major project to decommission the intermediate-level waste shaft was completed, and work was to begin later in the year.

[43] In March 2014, firefighters extinguished a small fire in an area used to store low-level nuclear waste.

The Office for Nuclear Regulation (ONR) concluded that "procedural non-compliances and behavioural practices" led to the fire, and served an improvement notice on Dounreay Site Restoration Limited.

[48] Plans were also announced to move about 700 kg (1,500 lb) of waste Highly Enriched Uranium to the United States.

[53] In April 2023, Dounreay became a division of Magnox Ltd as part of a simplified operating model for the NDA group.

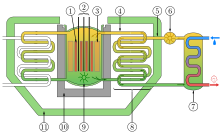

| 1 | Fissile Pu -239 core |

| 2 | Control rods |

| 3 | U -238 Breeder blanket |

| 4 | Primary NaK coolant loop |

| 5 | Secondary NaK coolant loop |

| 6 | Secondary NaK circulator |

| 7 | Secondary heat exchanger |

| 8 | Primary heat exchanger |

| 9 | Primary NaK circulator |

| 10 | Boronised graphite neutron shield |

| 11 | Radiation shield |