Dual-clutch transmission

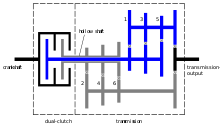

[1] The design is often similar to two separate manual transmissions with their respective clutches contained within one housing, and working as one unit.

[2][3] In car and truck applications, the DCT functions as an automatic transmission, requiring no driver input to change gears.

This was followed by various eastern European tractors through the 1970s (using manual operation via a single clutch pedal), then the Porsche 962 C racing car in 1985.

[3][7] By timing the operation of one clutch to engage at the precise moment that the other is disengaging, a DCT can shift gears without interrupting the torque supply to the wheels.

Several arrangements for the two clutches are possible, and are outlined below: The concept of a dual-clutch transmission was invented by French engineer Adolphe Kégresse in 1939.

[15][16] The Easidrive was offered as an option on Hillman and Singer models, however it was not a reliable device and many were replaced by conventional manual transmissions.

Porsche began development of DCTs for racing cars in the late 1970s,[17] due to the possibility of a DCT preventing a drop in boost during gear shifts on a turbocharged engine.

[2][1][24][23] Getrag began production of DCTs in 2008[26] and has supplied manufacturers including BMW,[27] Dacia,[28] Dodge, Ferrari,[29][30] Mercedes-Benz,[31] Ford, Mitsubishi, Renault, Smart and Volvo.

Other early high performance applications include the 2007 Nissan GT-R,[44][45] the 2008 Ferrari California,[46] the 2008 Mitsubishi Lancer Evolution X[47][48][49] and the 2009 Porsche 911 (997).

The purpose of the torque converter is to improve the smoothness of low-speed driving, through the elimination of jolting and shuddering sometimes found in DCTs at low speed.

For example, the Fortschritt ZT 300 has an Unterlastschaltstufe ('shifting under load') function, which needs to be pre-selected by the driver and then activated by pressing the clutch halfway down.

The dual-clutch transmission DQ200 of the Volkswagen Group was the subject of recall actions in several countries due to technical problems.

[59][60] Same year the Volkswagen Group recalled 1.6 million vehicles worldwide with the dry-running 7-speed dual-clutch transmission, type DQ200, including 257,000 in Germany.

- M: Motor

- A: Primary drive and driving shaft

- B: Dual clutch

- C: Driven shaft

- D: Layshaft, hollow, even gears

- E: Layshaft, odd gears

- F: Output