Dust collector

Dust collectors may be of single unit construction, or a collection of devices used to separate particulate matter from the process air.

[citation needed] Mist collectors remove particulate matter in the form of fine liquid droplets from the air.

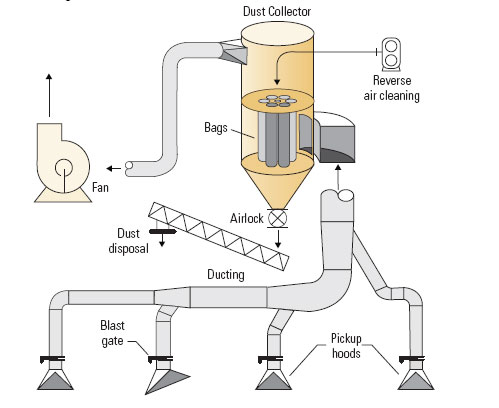

This is done via a ducting system, properly sized and manifolded to maintain a consistent minimum air velocity required to keep the dust in suspension for conveyance to the collection device.

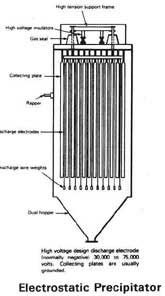

It can also be as complex as an electrostatic precipitator, a multistage baghouse, or a chemically treated wet scrubber or stripping tower.

[citation needed] Smaller dust collection systems use a single-stage vacuum unit to create suction and perform air filtration, where the waste material is drawn into an impeller and deposited into a container such as a bag, barrel, or canister.

[citation needed] Dust collection systems are often part of a larger air quality management program that also includes large airborne particle filtration units mounted to the ceiling of shop spaces and mask systems to be worn by workers.

[citation needed] In industry, round or rectangular ducts are used to prevent buildup of dust in processing equipment.

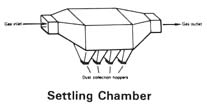

The increase of cross section area at the chamber reduces the speed of the dust-filled airstream and heavier particles settle out.

Advantages: 1) simple construction and low cost 2) maintenance free 3) collects particles without need of water.

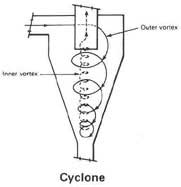

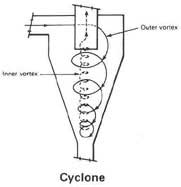

[citation needed] Centrifugal collectors use cyclonic action to separate dust particles from the gas stream.

The centrifugal force created by the circular flow throws the dust particles toward the wall of the cyclone.

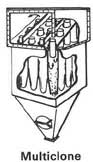

[citation needed] Multiple-cyclone separators consist of a number of small-diameter cyclones, operating in parallel and having a common gas inlet and outlet, as shown in the figure, and operate on the same principle as single cyclone separators—creating an outer downward vortex and an ascending inner vortex.

[citation needed] Secondary-air-flow separators use a secondary air flow, injected into the cyclone to accomplish several things.

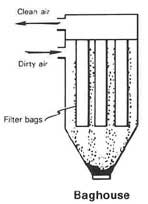

[citation needed] Commonly known as baghouses, fabric collectors use filtration to separate dust particulates from dusty gases.

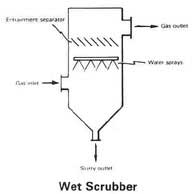

In these systems, the scrubbing liquid (usually water) comes into contact with a gas stream containing dust particles.

Greater contact of the gas and liquid streams yields higher dust removal efficiency.

[citation needed] The airborne particles receive a negative charge as they pass through the ionized field between the electrodes.

They are suitable for isolated, portable, or frequently moved dust-producing operations, such as bins and silos or remote belt-conveyor transfer points.

Advantages of unit collectors include small space requirements, the return of collected dust to main material flow, and low initial cost.

The screw-like action of the propellers moves the air in a straight-through parallel path, causing a helical flow pattern.

[citation needed] Motors are selected to provide sufficient power to operate fans over the full range of process conditions (temperature and flow rate).

[citation needed] A baghouse is an air pollution abatement device used to trap particulate by filtering gas streams through large fabric bags.

Various models are available, including free-hanging or ducted installations, vertical or horizontal mounting, and fixed or portable configurations.

Filter cartridges are made out of a variety of synthetic fibers and are capable of collecting sub-micrometre particles without creating an excessive pressure drop in the system.

[citation needed] Proper dust collection and air filtration is important in any work space.

Repeated exposure to wood dust can cause chronic bronchitis, emphysema, "flu-like" symptoms, and cancer.

Wood dust also frequently contains chemicals and fungi, which can become airborne and lodge deeply in the lungs, causing illness and damage.