Environmental impact of concrete

The presence of some substances in concrete, including useful and unwanted additives, can cause health concerns due to toxicity and (usually naturally occurring) radioactivity.

[citation needed] In some cases, incorporating certain compounds such as metals in the hydration process of cement immobilizes them in a harmless state and prevents them from being released freely elsewhere.

[12] The cement industry is one of the two largest producers of carbon dioxide (CO2), creating up to 5% of worldwide man-made emissions of this gas, of which 50% is from the chemical process and 40% from burning fuel.

These materials are slowly gaining popularity as additives, especially since they can potentially increase strength, decrease density, and prolong durability of concrete.

[21] The main obstacle to wider implementation of fly ash and slag may be largely due to the risk of construction with new technology that has not been exposed to long field testing.

Sublime of Somerville, Massachusetts uses a no-kiln electrochemical process, and Fortera captures carbon dioxide from conventional plants to make a new kind of cement.

This is achieved by directly injecting recycled liquid carbon dioxide from third-party industrial emitters into the concrete wet-mix stage during the manufacturing process.

The most effective method of production of this concrete would use the exhaust gas of a power plant, where an isolated chamber could control temperature and humidity.

The patented process of reduced-emissions concrete manufacture begins with the bonding of particles through liquid phase sintering, also referred to as reactive hydrothermal liquid-phase densification (rHLPD).

[34] A solution of water and CO2 penetrates the particles, reacting in ambient conditions to form a bond which creates reduced-lime, non-hydraulic calcium silicate cement (CSC).

[37] Another aspect to consider in carbon concrete is surface scaling due to cold climatic conditions and exposure to de-icing salt and freeze-thaw cycles (frost weathering).

[citation needed] Titanium dioxide (TiO2), a semiconductor material shown to exhibit photocatalytic behavior, has been used to remove nitrogen oxides (denoted NOx) from the atmosphere.

NOx species, i.e., nitric oxide and nitrogen dioxide, are atmospheric gases that contribute to acid rain and smog formation, both of which are the result of urban pollution.

[39] One proposed route of decreasing NOx concentrations, especially in urban settings, is to use photocatalytic TiO2 mixed into concrete to oxidize NO and NO2 to form nitrate.

The usage of embedded solar cells allows for on-site energy generation, which when coupled with batteries, would provide constant power throughout the day.

Dye-sensitized solar cells are particularly attractive due to its ease of mass production, either via roll-printing or painting, and a reasonably high efficiency of 10%.

[41] One example of the commercialization of this concept is the German company Discrete, which produces a dye-sensitized solar cell embedded concrete product.

[44] The road construction and maintenance industry consumes tons of carbon-intensive concrete every day to secure road-side and urban infrastructure.

Today, many construction companies and concrete manufacturers have cut the use of Portland cement in their mixtures due to its production process emitting significant amounts of greenhouse gases into the atmosphere.

Urban runoff tends to pick up gasoline, motor oil, heavy metals, trash and other pollutants from sidewalks, roadways and parking lots.

[54] A 2008 report by the United States National Research Council identified urban runoff as a leading source of water quality problems.

[56] If designed and layered properly, pervious concrete and other discreetly paved areas can also function as an automatic water filter by preventing certain harmful substances like oils and other chemicals from passing through.

Hot surfaces warm the city air through convection, so using materials that absorb less solar energy, such as high-albedo pavements, can reduce the flow of heat into the urban environment and moderate the UHIE.

[64] Another aspect to consider is thermal comfort effect, as well as the need for more mitigation strategies, which don’t threat the health and wellbeing of pedestrians particularly during heat waves.

[65] A study that appeared in Building and Environment in 2019 performed experiments to project the impact of heat waves and high albedo materials interactions in the northern Italian city of Milan.

By calculating the "Mediterranean Outdoor Comfort Index" (MOCI) in presence of a heat wave, where high albedo materials was used in all surfaces.

Contact with wet concrete can cause skin chemical burns due to the caustic nature of the mixture of cement and water (including rainwater).

Concrete debris was once routinely shipped to landfills for disposal, but recycling is increasing due to improved environmental awareness, governmental laws and economic benefits.

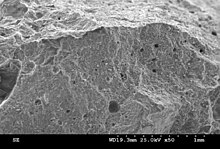

Concrete, which must be free of trash, wood, paper and other such materials, is collected from demolition sites and put through a crushing machine, often along with asphalt, bricks and rocks.

On 3 March 1983, a government-funded research team (the VIRL research.codep)[citation needed] approximated that almost 17% of worldwide landfill was by-products of concrete-based waste.