Breeder reactor

The designs use liquid metal as the primary coolant, to transfer heat from the core to steam used to power the electricity generating turbines.

Both have the advantage that they are liquids at room temperature, which is convenient for experimental rigs but less important for pilot or full-scale power stations.

Other FBR designs rely on the geometry of the fuel (which also contains uranium-238), arranged to attain sufficient fast neutron capture.

For this reason ordinary liquid water, being a moderator and neutron absorber, is an undesirable primary coolant for fast reactors.

Because large amounts of water in the core are required to cool the reactor, the yield of neutrons and therefore breeding of 239Pu are strongly affected.

Theoretical work has been done on reduced moderation water reactors, which may have a sufficiently fast spectrum to provide a breeding ratio slightly over 1.

[3] The type of coolants, temperatures, and fast neutron spectrum puts the fuel cladding material (normally austenitic stainless or ferritic-martensitic steels) under extreme conditions.

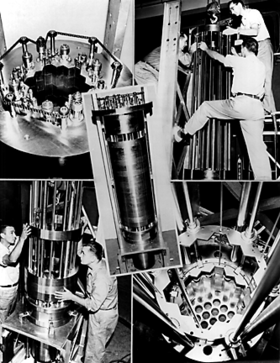

The IFR pyroprocessing system uses molten cadmium cathodes and electrorefiners to reprocess metallic fuel directly on-site at the reactor.

A quantity of natural uranium equivalent to a block about the size of a milk crate delivered once per month would be all the fuel such a 1 gigawatt reactor would need.

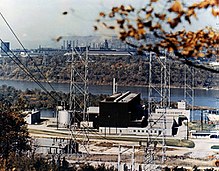

The third and final core of the Shippingport Atomic Power Station 60 MWe reactor was a light water thorium breeder, which began operating in 1977.

[11] The high fuel-efficiency of breeder reactors could greatly reduce concerns about fuel supply, energy used in mining, and storage of radioactive waste.

[21][22] In addition to seawater, the average crustal granite rocks contain significant quantities of uranium and thorium that with breeder reactors can supply abundant energy for the remaining lifespan of the sun on the main sequence of stellar evolution.

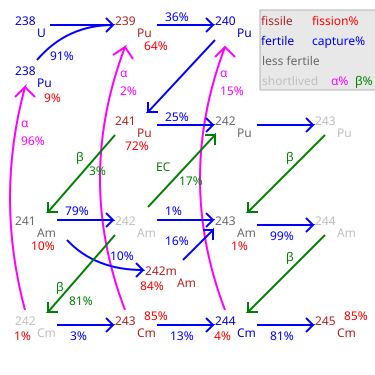

[23] No fission products have a half-lifein the range of 100 a–210 ka ... ... nor beyond 15.7 Ma[28] In broad terms, spent nuclear fuel has three main components.

Furthermore, only seven long-lived fission product isotopes have half-lives longer than a hundred years, which makes their geological storage or disposal less problematic than for transuranic materials.

As a result of this physical oddity, after several hundred years in storage, the activity of the radioactive waste from an FBR would quickly drop to the low level of the long-lived fission products.

If the fuel reprocessing methods used leave a large fraction of the transuranics in the final waste stream, this advantage would be greatly reduced.

[46] Theoretical models of breeders with liquid sodium coolant flowing through tubes inside fuel elements ("tube-in-shell" construction) suggest breeding ratios of at least 1.8 are possible on an industrial scale.

Early proposals for the breeder-reactor fuel cycle posed an even greater proliferation concern because they would use PUREX to separate plutonium in a highly attractive isotopic form for use in nuclear weapons.

[11] More conventional water-based reprocessing systems include SANEX, UNEX, DIAMEX, COEX, and TRUEX, and proposals to combine PUREX with those and other co-processes.

Similar to uranium-fueled designs, the longer the fuel and fertile material remain in the reactor, the more of these undesirable elements build up.

In 2010 the International Panel on Fissile Materials said "After six decades and the expenditure of the equivalent of tens of billions of dollars, the promise of breeder reactors remains largely unfulfilled and efforts to commercialize them have been steadily cut back in most countries".

In the documentary Pandora's Promise, a case is made for breeder reactors because they provide a real high-kW alternative to fossil fuel energy.

[85] However, in 2015 Rosenergoatom postponed construction indefinitely to allow fuel design to be improved after more experience of operating the BN-800 reactor, and among cost concerns.

Lead coolant temperature would be around 540 °C, giving a high efficiency of 43%, primary heat production of 700 MWt yielding electrical power of 300 MWe.

[citation needed] In 2006 the United States, France, and Japan signed an "arrangement" to research and develop sodium-cooled fast reactors in support of the Global Nuclear Energy Partnership.

In 2011, Sorensen founded Flibe Energy, a company aimed to develop 20–50 MW LFTR reactor designs to power military bases.

[93][94][95][96] In October 2010 GE Hitachi Nuclear Energy signed a memorandum of understanding with the operators of the US Department of Energy's Savannah River Site, which should allow the construction of a demonstration plant based on the company's S-PRISM fast breeder reactor prior to the design receiving full Nuclear Regulatory Commission licensing approval.

[97] In October 2011 The Independent reported that the UK Nuclear Decommissioning Authority (NDA) and senior advisers within the Department for Energy and Climate Change (DECC) had asked for technical and financial details of PRISM, partly as a means of reducing the country's plutonium stockpile.

This is contrary to many media reports, which have popularized the concept as a candle-like reactor with a burn region that moves down a stick of fuel.

Under this scenario, the reconfiguration of fuel rods is accomplished remotely by robotic devices; the containment vessel remains closed during the procedure, and there is no associated downtime.