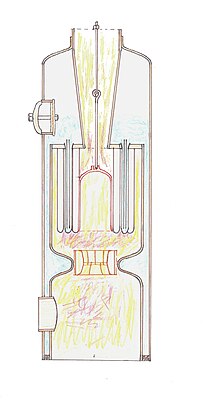

Field-tube boiler

For this reason, thimble tubes can only be short, so are used in large numbers, and usually horizontally as their flow is not coherent enough to benefit from a gravity gradient.

[1] One drawback of the field-tube is a tendency for mud and scale to accumulate in the bottom of the tube, potentially blocking circulation.

Providing an excessive dead space there as a mud reservoir would have poor circulation, thus risking local overheating.

Where a simple vertical boiler requires additional heating surface, particularly where this is directly exposed to the furnace so as to raise steam more rapidly, field-tubes may be installed in the roof of the firebox, almost down to the level of the firebed.

As they are only mounted at one end and are free to expand in the heat, many of the usual expansion problems of thermic syphons are avoided.

Any unburned combustion gases leaving the first chamber are heated by this incandescent ring and together with the supply of secondary air are encouraged to ignite.

A steel radiation bell is hung in the centre of the chamber, beneath the outlet flue, and the combustion gases are directed to pass over this, heating it.

The USS Georgia (BB-15) built by the Bath Iron Works in Maine and her launching in October 1904 with steam provided by twenty-four coal-fired Niclausse Boilers.

With careful design and regular maintenance the type gained a reputation for reliability and the quick replacement of a failed tube,[11] which made it suitable for naval practice, less so for commercial use.

Niclausse boilers gave poor fuel economy when coupled with turbines operating at low speed, in addition to copious quantities of smoke and sparks.

By 1901, the Royal Navy had ordered eight Dürr boilers from Germany, to be installed as a trial on board the Marathon-class cruiser HMS Medusa.