Film blowing machine

Parts include: screw and barrel, motor, inverter, heaters, die head, winder, and tower.

The screw and material barrel may be made from a nitrogen-treated chromium-molybdenum-aluminum alloy.

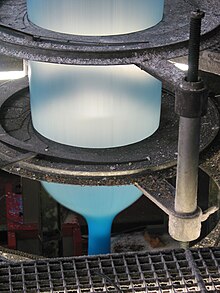

it is heated and melted into a viscous liquid between rotating screws and barrels of the extruder.

This tube is then carefully inflated, so there is no risk of tearing, into a bubble by injecting it with air.

Now that the layers are close, a series of nip rollers flatten the layers together to form a two-layered plastic film that is then wound onto a cylindrical roll for packaging purposes.