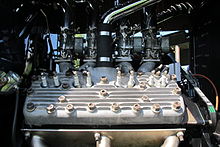

Ford flathead V8 engine

It was a staple of hot rodders in the 1950s, and it remains famous in the classic car hobbies even today, despite the huge variety of other popular V8s that followed.

Such an arrangement transferred exhaust heat to the block, imposing a large cooling load; it required far more coolant and radiator capacity than equivalent overhead-valve V8 engines.

Ford flathead V8s were notorious for cracking blocks if their barely adequate cooling systems were overtaxed (such as in trucking or racing).

The simple design left much room for improvement, and the power available after even low cost modifications was usually substantially more than could be obtained from an overhead-valve inline six-cylinder engine of similar displacement[citation needed].

For these reasons, the flathead Ford became a favorite among hot-rodders, and this in turn led to a rich supply of aftermarket performance parts.

Making it practical for the latter was an example of the production development needed to bring a V8 engine to the widely affordable segment of the market.

[4] Most V engines of the time had multiple cylinder blocks bolted to a common crankcase (itself a separate casting).

The gas flow past the rough sand castings could be greatly improved by polishing the passages.

In early blocks, some cylinder walls were extremely thin due to cores shifting during casting.

The engines built from 1932 to 1935 had poured main bearings which required skill and machine shop equipment to overhaul.

For powering the fuel pump, the camshaft is fitted with an extra cam located in the bearing on the flywheel side.

[11] Ford products used high oil pressure for lubrication for the main and rod bearings, as do all modern vehicle combustion engines.

For this reason, bank robber Clyde Barrow preferred to steal Fords as getaway vehicles.

As a side benefit to a prospective purchaser of a used vehicle, this also enabled the condition of the connecting rod and main bearings to be determined indirectly by observation of the oil pressure gauge after the vehicle was warmed up, provided that oil of normal viscosity was in use.

In the 1950s shortcut exhaust outlets with manually removed covers were added to street machines in emulation of vehicles intended for high speed straight line racing on dry lake beds, typically located just behind the front wheel, although chromed external runners sometimes extended to just forward of the rear wheel.

This style exhaust was also used legally in sanctioned drag racing and illegally in unsanctioned performance demonstrations.

More extreme modifications were to improve the airflow by removing material from the top of the block between the valves and the cylinders (called relieving), increasing the size of the inlet and exhaust passages (called porting), and by polishing the sand-cast surfaces to improve air flow.

Changing the camshaft to a higher performance version required head removal so that the valves could be held up out of the way, so this was usually done only as part of a substantial rework of the basic engine.

Even many inline six-cylinder engines from that period could be modified to produce more reliable and practical power than Ford V-8s, as the Ford flathead V-8 is saddled with many design features that make modifying it for true high-performance use difficult and expensive compared with other V-8s.

As modern OHV V-8s became available and affordable in salvage yards, the Ford flathead V-8 rapidly disappeared from the hot-rodding scene.

Today the flat-head Ford is mainly used in "retro" hot-rod builds by builders more interested in an historic feel and recreating history than performance.

In the late 1940s, their aircraft line became unprofitable, but they found renewed profitability in aftermarket parts for tractors—transmissions, engines, and accessories.

[19] The block was cast as a single piece (monobloc) for durability, and a single-barrel carburetor fed the engine.

[citation needed] 1935's V8-48 saw compression drop to 6.3:1, but power climb to 85 hp (63 kW), and torque was rated at 144 lb⋅ft (195 N⋅m).

[19] This was done to provide a more powerful engine for the Mercury cars, which Ford Motor Company started making in 1939.

This final flathead used a more conventional distributor driven at a right angle to the crankshaft and located at the right front of the engine where it was readily accessible.

In 1952 Ford France (who called this engine the Aquilon) created a somewhat bored out version displacing 144 cu in (2.4 L).

This engine has overhead valves and hemispherical combustion chambers; it produced 138 hp (103 kW) in its most powerful version.

[21] French-built 255 engines were fitted to the Simca Unic Marmon Bocquet (SUMB) light trucks of the French military.

[22] The largest displacement version (at 337 cu in [5.5 L]) of the production Ford flathead V8 engine was designed for large truck service.