Bakelite

It was used in electrical insulators, radio and telephone casings, and such diverse products as kitchenware, jewelry, pipe stems, children's toys, and firearms.

[4] The creation of a synthetic plastic was revolutionary for the chemical industry, which at the time made most of its income from cloth dyes and explosives.

[6] Leo Baekeland was already wealthy due to his invention of Velox photographic paper when he began to investigate the reactions of phenol and formaldehyde in his home laboratory.

[citation needed] Baekeland's initial intent was to find a replacement for shellac, a material in limited supply because it was made naturally from the secretion of lac insects (specifically Kerria lacca).

[5] By controlling the pressure and temperature applied to phenol and formaldehyde, he produced a hard moldable material that he named Bakelite, after himself.

[12] He also filed for patent protection in other countries, including Belgium, Canada, Denmark, Hungary, Japan, Mexico, Russia, and Spain.

[15]: 172–174 Blocks or rods of cast resin, also known as "artificial amber", were machined and carved to create items such as pipe stems, cigarette holders, and jewelry.

[9]: 58–59 [18] A filing for a trademark featuring the letter B above the mathematical symbol for infinity was made August 25, 1925, and claimed the mark was in use as of December 1, 1924.

The range of colors that were available included "black, brown, red, yellow, green, gray, blue, and blends of two or more of these".

; lacquers, for protecting the surface of hardware; enamels, for giving resistive coating to industrial equipment; Laminated Bakelite, used for silent gears and insulation; and molding material, from which are formed innumerable articles of utility and beauty.

[18]: 17 In a 1925 report, the United States Tariff Commission hailed the commercial manufacture of synthetic phenolic resin as "distinctly an American achievement", and noted that "the publication of figures, however, would be a virtual disclosure of the production of an individual company".

Translucent jewelry, poker chips and other items made of phenolic resins were introduced in the 1930s or 1940s by the Catalin company under the Prystal name.

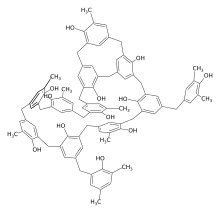

It begins with the heating of phenol and formaldehyde in the presence of a catalyst such as hydrochloric acid, zinc chloride, or the base ammonia.

This creates a liquid condensation product, referred to as Bakelite A, which is soluble in alcohol, acetone, or additional phenol.

However, the high temperatures required to create this tend to cause violent foaming of the mixture when done at standard atmospheric pressure, which results in the cooled material being porous and breakable.

[4]: 67 [9]: 38–39 Molded Bakelite forms in a condensation reaction of phenol and formaldehyde, with wood flour or asbestos fiber as a filler, under high pressure and heat in a time frame of a few minutes of curing.

Bakelite resin could be provided either as powder or as preformed partially cured slugs, increasing the speed of the casting.

A phenolic sheet is a hard, dense material made by applying heat and pressure to layers of paper or glass cloth impregnated with synthetic resin.

[30] Bakelite phenolic sheet is produced in many commercial grades and with various additives to meet diverse mechanical, electrical, and thermal requirements.

Important projects included the Liberty airplane engine,[39] the wireless telephone and radio phone,[40] and the use of micarta-bakelite propellers in the NBS-1 bomber and the DH-4B aeroplane.

[45] It was soon found in myriad other consumer products ranging from pipe stems and buttons to saxophone mouthpieces, cameras, early machine guns, and appliance casings.

[62] During World War II, Bakelite was used in a variety of wartime equipment including pilots' goggles and field telephones.

They still appear in some applications where their specific properties are required, such as small precision-shaped components, molded disc brake cylinders, saucepan handles, electrical plugs, switches and parts for electrical irons, printed circuit boards, as well as in the area of inexpensive board and tabletop games produced in China, Hong Kong, and India.

Items such as billiard balls, dominoes and pieces for board games such as chess, checkers, and backgammon are constructed of Bakelite for its look, durability, fine polish, weight, and sound.

Bakelite continues to be used for wire insulation, brake pads and related automotive components, and industrial electrical-related applications.

[12] Producing hard, compact, insoluble, and infusible condensation products of phenols and formaldehyde marked the beginning of the modern plastics industry.