Compact linear Fresnel reflector

This concentrated energy is transferred through the absorber into some thermal fluid (this is typically oil capable of maintaining a liquid state at very high temperatures).

The first linear Fresnel reflector solar power system was developed in Italy in 1961 by Giovanni Francia of the University of Genoa.

[3] Research published in 2010 showed that higher concentrations and/or higher acceptance angles could be obtained by using nonimaging optics[4] to explore different degrees of freedom in the system such as varying the size and curvature of the heliostats, placing them at a varying height (on a wave-shape curve) and combining the resulting primary with nonimaging secondaries.

A key component that makes all LFR's more advantageous than traditional parabolic trough mirror systems is the use of "Fresnel reflectors".

The reflectors of a CLFR are typically aligned in a north-south orientation and turn about a single axis using a computer controlled solar tracker system.

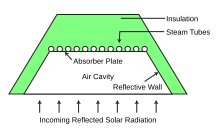

The basic design of the absorber for the CLFR system is an inverted air cavity with a glass cover enclosing insulated steam tubes, shown in Fig.2.

In April 2008, AREVA opened a large factory in Las Vegas, Nevada to produce linear Fresnel reflectors.

The solar thermal power plant uses a standard linear Fresnel optical design (not CLFR) and has an electrical capacity of 1.4 MW.

A salt temperature of up to 550 °C (823 K; 1,022 °F) facilitates the running of a conventional steam turbine for electrical generation, enhanced oil recovery, or desalination.

Since 2015 FRENELL GmbH, a management buy-out of Novatec Solar, took over the commercial development of the direct molten salt technology.

[17] In China, a 50 MW commercial scale Fresnel project using molten salt as its heat transfer medium has been under construction since 2016.