Enhanced oil recovery

As a means of boosting domestic oil production, the US federal tax code began to include incentives for EOR in 1979.

Crude oil development and production can include up to three distinct phases: primary, secondary, and tertiary (or enhanced) recovery.

The fluid most commonly used for miscible displacement is carbon dioxide because it reduces the oil viscosity and is less expensive than liquefied petroleum gas.

[18][19] In these applications, between one-half and two-thirds of the injected CO2 returns with the produced oil and is usually re-injected into the reservoir to minimize operating costs.

[23] According to a study done by Kovscek, using small slugs of both carbon dioxide and water allows for quick recovery of the oil.

Continuous injection of air or other gas mixture with high oxygen content will maintain the flame front.

Heat from the fire reduces oil viscosity and helps vaporize reservoir water to steam.

The steam, hot water, combustion gas and a bank of distilled solvent all act to drive oil in front of the fire toward production wells.

Dilute solutions of surfactants such as petroleum sulfonates or biosurfactants such as rhamnolipids may be injected to lower the interfacial tension or capillary pressure that impedes oil droplets from moving through a reservoir, this is analyzed in terms of the bond number, relating capillary forces to gravitational ones.

Special formulations of oil, water and surfactant, microemulsions, can be particularly effective in reducing interfacial tension.

Application of these methods is usually limited by the cost of the chemicals and their adsorption and loss onto the rock of the oil containing formation.

Primary surfactants usually have co-surfactants, activity boosters, and co-solvents added to them to improve stability of the formulation.

Nanofluids perform many functions in EOR of oil fields, including pore disjoining pressure, channel plugging, interfacial tension reduction, mobility ratio, wettability alteration, and asphaltene precipitation prevention.

Nanofluids facilitates disjoining pressure to remove sediment entrapped oil via aggregation at the interface.

In the first approach, bacterial cultures mixed with a food source (a carbohydrate such as molasses is commonly used) are injected into the oil field.

[37][better source needed] After the injected nutrients are consumed, the microbes go into near-shutdown mode, their exteriors become hydrophilic, and they migrate to the oil-water interface area, where they cause oil droplets to form from the larger oil mass, making the droplets more likely to migrate to the wellhead.

The third approach is used to address the problem of paraffin wax components of the crude oil, which tend to precipitate as the crude flows to the surface, since the Earth's surface is considerably cooler than the petroleum deposits (a temperature drop of 9–10–14 °C per thousand feet of depth is usual).

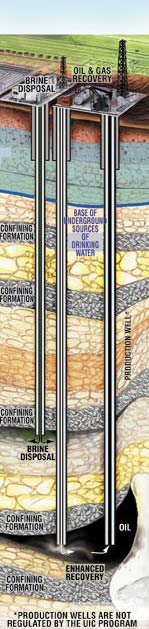

[42] Enhanced oil recovery wells typically pump large quantities of produced water to the surface.

[47] A 2020 review found that scientific papers were roughly evenly split on the question of whether carbon capture with EOR increased or decreased emissions.

[16] In the US, regulations can both assist and slow down the development of EOR for use in carbon capture & utilization, as well as general oil production.

[49] The Inflation Reduction Act of 2022 (IRA) updates tax credit law to encourage the use of carbon capture and storage.

Tax incentives under the law provide up to $85/tonne for CO2 capture and storage in saline geologic formations or up to $60/tonne for CO2 used for enhanced oil recovery.

[50] The Internal Revenue Service relies on documentation from the corporation to substantiate claims on how much CO2 is being sequestered, and does not perform independent investigations.

[51] In 2020, a federal investigation found that claimants for the 45Q tax credit failed to document successful geological storage for nearly $900 million of the $1 billion they had claimed.

[53] The agency in turn delegated some of this power to its own Underground Injection Control Program,[53] and much of the rest of this regulatory authority to state and tribal governments, making much of EOR regulation a localized affair under the minimum requirements of the SDWA.

[53][54] The EPA then collects information from these local governments and individual wells to ensure they follow overall federal regulation, such as the Clean Air Act, which dictates reporting guidelines for any Carbon Dioxide sequestration operations.

[53][55] Beyond the atmospheric concerns, most of these federal guidelines are to ensure that the Carbon Dioxide injection causes no major damage to America's waterways.

[57] EPA has issued Underground Injection Control (UIC) regulations in order to protect drinking water sources.