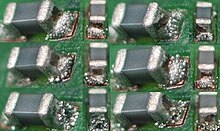

Graping

The increased surface oxidation is the result of smaller printed paste deposit volumes that cause a diminished surface area to flux ratio of the solder particle, resulting in flux exhaustion.

[1][3] The graping phenomenon can be resolved utilizing proper solder materials in addition to correct reflow profile settings.

Solder powders are available that provide a tighter distribution range as well as a high oxidation barrier.

This barrier not only improves the paste release from the stencil, but also provides an ideal surface area-to-volume ratio.

Future solder paste flux formulations provide sufficient activity paired with re-oxidation mitigation capabilities.