Hard disk drive

Hard disk drives were introduced by IBM in 1956,[5] and were the dominant secondary storage device for general-purpose computers beginning in the early 1960s.

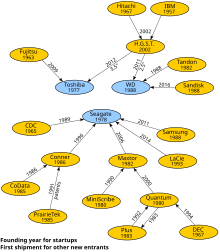

More than 224 companies have produced HDDs historically, though after extensive industry consolidation, most units are manufactured by Seagate, Toshiba, and Western Digital.

[14] Though SSDs have four to nine times higher cost per bit,[15][16] they are replacing HDDs in applications where speed, power consumption, small size, high capacity and durability are important.

Motion of the head array depended upon a binary adder system of hydraulic actuators which assured repeatable positioning.

Later models of removable pack drives, from IBM and others, became the norm in most computer installations and reached capacities of 300 megabytes by the early 1980s.

Powerful rare earth magnet materials became affordable during this period and were complementary to the swing arm actuator design to make possible the compact form factors of modern HDDs.

As the 1980s began, HDDs were a rare and very expensive additional feature in PCs, but by the late 1980s, their cost had been reduced to the point where they were standard on all but the cheapest computers.

[43] In 2019, Western Digital closed its last Malaysian HDD factory due to decreasing demand, to focus on SSD production.

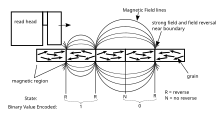

Information is written to and read from a platter as it rotates past devices called read-and-write heads that are positioned to operate very close to the magnetic surface, with their flying height often in the range of tens of nanometers.

MAMR hard drives have a microwave-generating spin torque generator (STO) on the read/write heads which allows physically smaller bits to be recorded to the platters, increasing areal density.

The servo feedback optimizes the signal-to-noise ratio of the GMR sensors by adjusting the voice coil motor to rotate the arm.

Modern disk firmware is capable of scheduling reads and writes efficiently on the platter surfaces and remapping sectors of the media that have failed.

The extra bits themselves take up space on the HDD, but allow higher recording densities to be employed without causing uncorrectable errors, resulting in much larger storage capacity.

[85][86] By contrast, HGST (now part of Western Digital) focused on developing ways to seal helium-filled drives instead of the usual filtered air.

[88] HAMR is expected to ship commercially in late 2024,[89] after technical issues delayed its introduction by more than a decade, from earlier projections as early as 2009.

[98][99][100] Two-dimensional magnetic recording (TDMR)[82][101] and "current perpendicular to plane" giant magnetoresistance (CPP/GMR) heads have appeared in research papers.

Furthermore, many HDDs store their firmware in a reserved service zone, which is typically not accessible by the user, and is not included in the capacity calculation.

The process of initializing these logical blocks on the physical disk platters is called low-level formatting, which is usually performed at the factory and is not normally changed in the field.

In the early days of computing, the total capacity of HDDs was specified in seven to nine decimal digits frequently truncated with the idiom millions.

[121] The difference between the decimal and binary prefix interpretation caused some consumer confusion and led to class action suits against HDD manufacturers.

The plaintiffs argued that the use of decimal prefixes effectively misled consumers, while the defendants denied any wrongdoing or liability, asserting that their marketing and advertising complied in all respects with the law and that no class member sustained any damages or injuries.

With increasing sales of microcomputers having built-in floppy-disk drives (FDDs), HDDs that would fit to the FDD mountings became desirable.

By 2009, all manufacturers had discontinued the development of new products for the 1.3-inch, 1-inch and 0.85-inch form factors due to falling prices of flash memory,[127][128] which has no moving parts.

Defragmentation is a procedure used to minimize delay in retrieving data by moving related items to physically proximate areas on the disk.

A current, widely used standard for the "buffer-to-computer" interface is 3.0 Gbit/s SATA, which can send about 300 megabyte/s (10-bit encoding) from the buffer to the computer, and thus is still comfortably ahead of today's[as of?]

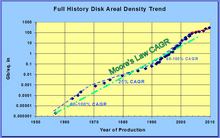

Because heat and vibration limit rotational speed, advancing density becomes the main method to improve sequential transfer rates.

[133] Other performance considerations include quality-adjusted price, power consumption, audible noise, and both operating and non-operating shock resistance.

An exception to this are hermetically sealed, helium-filled HDDs that largely eliminate environmental issues that can arise due to humidity or atmospheric pressure changes.

A 2011 summary of research, into SSD and magnetic disk failure patterns by Tom's Hardware summarized research findings as follows:[140] As of 2019[update], Backblaze, a storage provider, reported an annualized failure rate of two percent per year for a storage farm with 110,000 off-the-shelf HDDs with the reliability varying widely between models and manufacturers.

[7] To minimize cost and overcome failures of individual HDDs, storage systems providers rely on redundant HDD arrays.