Hele-Shaw clutch

It was named after its inventor, Professor Henry Selby Hele-Shaw, who was noted for his work in viscosity and flows through small gaps between parallel plates.

As the Hele-Shaw clutch did not rely on friction, it generated only a fraction of the heat of other designs and its construction was easily able to disperse this.

The use of oil was also inherent, unlike other clutches that still basically relied on dry friction, with lubrication to avoid overheating when slipping.

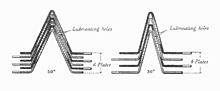

[3] The multi-plate Hele-Shaw clutch with six alternating steel and phosphor bronze plates running in graphite powder was used in racecars such as the 1921 Grand Prix Sunbeams.

[6] [clarification needed] The Hele-Shaw clutch was also used for extremely high powers in both industry and for marine propulsion, of 1,000 hp and more.

[7] Engaging each clutch in turn provided a forwards and reverse motion, one direction being geared down in speed and increased in torque.