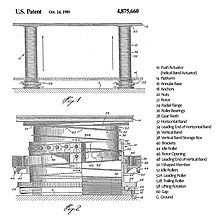

Helical band actuator

The actuator forms a high-capacity telescoping tubular column (lifting capacities to 25,000 pounds, travel to 40 feet).

[2] Gagnon developed the actuator to substitute hydraulic cylinders in stage and orchestra lift systems.

For lifts at grade, housings for the rods are often sunk into support holes, known as caissons, that are inaccessible and often complicated by groundwater levels.

Gagnon's actuator eliminates caissons and reduces the volume of unusable space below the platform of the lift.

Helical band actuators require a separate lateral support mechanism, usually provided in the form of guide rails or self-guiding frame, such as a pantograph (e.g. a scissor lift).