Helix angle

Note that while the terminology directly refers to screws, these concepts are analogous to most mechanical applications of the helix angle.

where The helix angle is crucial in mechanical engineering applications that involve power transfer and motion conversion.

Cutting a single helical groove into a screw-stock cylinder yields what is referred to as a single-thread screw.

The friction value is dependent on the materials of the screw and interacting nut, but ultimately the efficiency is controlled by the helix angle.

The efficiency can be plotted versus the helix angle for a constant friction, as shown in the adjacent diagram.

Due to difficulties in forming the thread, helix angle greater than 30° are rarely used.

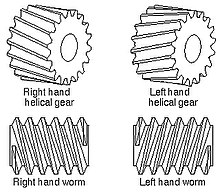

[4] In helical and worm gears, the helix angle denotes the standard pitch circle unless otherwise specified.

[1] Application of the helix angle typically employs a magnitude ranging from 15° to 30° for helical gears, with 45° capping the safe operation limit.

[5] In its typical parallel arrangement, meshing helical gears requires that the helix angles are of the same magnitude and cut oppositely .