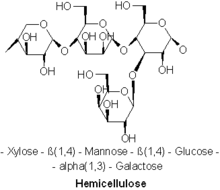

Hemicellulose

A hemicellulose (also known as polyose) is one of a number of heteropolymers (matrix polysaccharides), such as arabinoxylans, present along with cellulose in almost all terrestrial plant cell walls.

[6] Based on the structural difference, like backbone linkages and side groups, as well as other factors, like abundance and distributions in plants, hemicelluloses can be categorized into four groups as following:[4] 1) xylans, 2) mannans; 3) mixed linkage β-glucans; 4) xyloglucans.

Xylans usually consist of a backbone of β-(1→4)-linked xylose residues and can be further divided into homoxylans and heteroxylans.

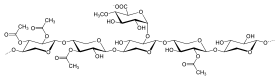

Arabinoxylans and glucuronoarabinoxylans contain arabinose residues attached to the backbone[7]The mannan-type hemicellulose can be classified into two types based on their main chain difference, galactomannans and glucomannans.

[5] The two most common types of xyloglucans in plant cell walls are identified as XXXG and XXGG.

[9][10] Mannan synthase, a particular enzyme in CSLA, is responsible for the addition of mannose units to the backbone.

[10] Xyloglucan backbone synthesis is mediated by cellulose synthase-like protein family C (CSLC), particularly glucan synthase, which adds glucose units to the chain.

[9][10] Backbone synthesis of xyloglucan is also mediated in some way by xylosyltransferase, but this mechanism is separate to its transferase function and remains unclear.

[9][10] Xylan backbone synthesis, unlike that of the other hemicelluloses, is not mediated by any cellulose synthase-like proteins.

[10] Backbone synthesis is mediated by enzymes in cellulose synthase-like protein families F and H (CSLF and CSLH), specifically glucan synthase.

[7] Hemicellulose dominates the middle lamella of the plant cell, unlike cellulose which is primarily found in the secondary layers.

This allows for hemicellulose to provide middle-ground support for the cellulose on the outer layers of the plant cell.

In few cell walls, hemicellulose will also interact with lignin to provide structural tissue support of more vascular plants.

[3][19] There are many ways to obtain hemicellulose; all of these rely on extraction methods through hardwood or softwood trees milled into smaller samples.

In hardwoods the main hemicellulose extract is glucuronoxlyan (acetylated xylans), while galactoglucomannan is found in softwoods.

Following this, a hot water extraction process, also known as autohydrolysis or hydrothermal treatment, is utilized with the addition of acids and bases to change the yield size and properties.

When pretreatment is done with bases (for instance sodium or potassium hydroxide) this destroys the structure of the lignin.

[citation needed] The hot water process is operated at a temperature range of 160 to 240 degrees Celsius in order to maintain the liquid phase.

This is done above the normal boiling point of water to increase the solubilization of the hemicellulose and the depolymerization of polysaccharides.