History of the oil shale industry

[5] In the 10th century, the Arabian physician Masawaih al-Mardini (Mesue the Younger) described a method of extraction of oil from "some kind of bituminous shale".

[5] In Skåne, the Swedish alum shale dating from the Cambrian and Ordovician periods was used for extracting potassium aluminium sulfate by roasting it over fire as early as 1637.

[5] The British Crown granted a patent in 1694 to three persons named Martin Eele, Thomas Hancock and William Portlock who had "found a way to extract and make great quantities of pitch, tarr, and oyle out of a sort of stone.

"[16] In 1781, Archibald Cochrane, 9th Earl of Dundonald, registered a patent for an extraction process to produce tar, pitch and oil from coal and bituminous shales, using masonry retorts and wooden condensers.

Data on physical and chemical properties of Ukhta oil shale was published by a correspondent member of the Russian Academy Tertii Bornovolokov in 1809.

[19] In the 1830s Germain Henri Hess investigated Baltic oil shales with resulting determination of the semicoking process product yields.

[18] Oil shale in Australia was referred to for the first time by François Péron, et al., in Voyage de Découverte aux Terres Australes[20] which was published in Paris in 1807, describing what was probably torbanite from the Newnes deposit.

[17][24] In 1846 the Canadian physician and geologist Abraham Gesner invented a process for retorting an illuminating liquid from coal, bitumen and oil shale.

[25][28][29] Commercial scale shale oil extraction from lamosite started in 1859 by Robert Bell in Broxburn, West Lothian.

[47] The oil shale industry expanded immediately before World War I because of limited access to conventional petroleum resources and the mass production of automobiles and trucks, which accompanied an increase in gasoline consumption.

[48] First attempt to produce oil from the western deposits was made in Nevada by local businessman Robert Catlin by acquiring oil-shale properties in the 1890s and erecting the first retorts in 1915 and 1916.

[31] The first attempts to exploit the Green River Formation deposit was made by establishment of The Oil Shale Mining Company in 1916.

[54][55] In 1925–1929, the retort was also tested by the United States Bureau of Mines in their Oil Shale Experiment Station at Anvil Point in Rifle, Colorado.

[59] when a group of geologists, led by Nikolay Pogrebov, was sent to Estonia to organise the mining of oil shale and its transportation to Saint Petersburg (then known as Petrograd).

In June 1916, the first tonnes of oil shale were mined at Pavandu and delivered to Saint Petersburg Polytechnical University for large-scale experiments.

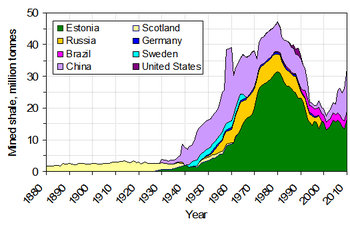

[31] Although the Estonian, Russian and Chinese oil shale industries continued to grow after World War II, most other countries abandoned their projects due to high processing costs and the availability of cheaper petroleum.

[2][23] The shale oil extraction in Australia was discontinued in 1952 due to ceasing of government funding, in France in 1957, in Britain and South Africa in 1962, and in Sweden and Spain in 1966.

[76][81] In Germany only Rohrbach Zement (now part of Holcim) in Dotternhausen continued using oil shale for cement, power and thermal energy production.

[97] In 1951, the United States Department of Defense became interested in oil shale as an alternative resource for producing a jet fuel.

[99] In 1964 the Avril Point demonstration facility was leased by Colorado School of Mines and was used by Mobil-led consortium (Mobil, Humble, Continental, Amoco, Phillips and Sinclair) for further development of that type of retort.

[31][34] In 1953, Sinclair Oil Corporation developed an in-situ processing method using existing and induced fractures between vertical wells.

[31] In the early 1960s TOSCO (The Oil Shale Corporation) opened an underground mine and built an experimental plant near Parachute, Colorado.

[52] In 1972, the first modified in situ oil shale experiment in the United States was conducted by Occidental Petroleum at Logan Wash, Colorado.

Year later Ashland, Cleveland Cliffs and Sohio exited the Colony Shale Oil Project near Parachute, Colorado.

On 2 May 1982, known as "Black Sunday", Exxon cancelled the Colony project due to low oil-prices and increased expenses, laying off more than 2,000 workers.

[110][111] In 1986, President Ronald Reagan signed into law the Consolidated Omnibus Budget Reconciliation Act of 1985 which among other things abolished the United States' Synthetic Liquid Fuels Program.

[118] In Romania, a 990 MW oil shale-fired power plant at Crivina operated in 1983–1988; however, it was decommissioned due to inefficiency and technical problems.

[18][119] In Brazil a 2,400 tons per day semi-works retort (the Irati Profile Plant) was brought on line in 1972, and began limited commercial operation in 1980.

[125] In Australia, the Alberta Taciuk technology was used for a demonstration-scale processing plant at the Stuart Deposit near Gladstone, Queensland, which produced between 2000 and 2004 over 1.5 million barrels (240×10^3 m3) of shale oil.

[128] The Energy Policy Act of 2005 introduced a commercial leasing program for oil shale and tar sands resources on public lands within the states of Colorado, Utah, and Wyoming.