Hollow-point bullet

Solid lead bullets, when cast from a soft alloy, will often deform and provide some expansion if they hit the target at a high velocity.

Although such bullet designs were quickly outlawed for use in warfare (in 1898, the Germans complained they breached the Laws of War), they steadily gained ground among hunters due to the ability to control the expansion of the new high velocity cartridges.

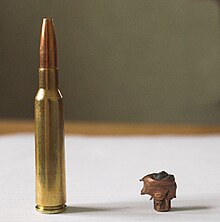

[1][2] Modern hollow-point bullet designs use many different methods to provide controlled expansion, including: When a hollow-point hunting bullet strikes a soft target, the pressure created in the pit forces the material (usually lead) around the inside edge to expand outwards, increasing the axial diameter of the projectile as it passes through.

The greater frontal surface area of the expanded bullet limits its depth of penetration into the target and causes more extensive tissue damage along the wound path.

This jacket provides additional strength to the bullet, increases penetration, and can help prevent it from leaving deposits of lead inside the bore.

This allows the manufacturer to maintain a greater consistency in tip shape and thus aerodynamic properties among bullets of the same design, at the expense of a slightly decreased ballistic coefficient and higher drag.

The Saint Petersburg Declaration of 1868 banned exploding projectiles of less than 400 grams, along with weapons designed to aggravate injured soldiers or make their death inevitable.

A valid firearms certificate allows the holder to use ball, full metal jacket, hollow point and ballistic-tipped ammunition for range use and vermin control.

Until recently[vague] all expanding ammunition fell under section 5 of the Firearms Act 1968 and was only allowed when conditions were entered onto an FAC by the police.

After announcing consideration of using hollow point ammunition for side arms, with a possible start date of 2018,[10] the United States Army began production of M1153 special purpose ammunition for the 9×19mm Parabellum with a 147-grain (9.5 g) jacketed hollow point bullet at 962 feet (293 m) per second for use in situations where limited over-penetration of targets is necessary to reduce collateral damage.

The bullets were coated with a black colored, paint-like lubricant called "Lubalox", and loaded into nickel-plated brass cases, which made them visually stand out from other ammunition.

[15][16] A concern was raised by the president of the American College of Emergency Physicians (ACEP) that the sharp edges of the jacket could cut medical personnel's skin and risk spread of disease.

[17][18] Winchester responded to the media criticism of the Black Talon line by removing it from the commercial market and only selling it to law enforcement distributors.