Industrial wastewater treatment

[citation needed] Battery manufacturers specialize in fabricating small devices for electronics and portable equipment (e.g., power tools), or larger, high-powered units for cars, trucks and other motorized vehicles.

Pollutants generated at manufacturing plants includes cadmium, chromium, cobalt, copper, cyanide, iron, lead, manganese, mercury, nickel, silver, zinc, oil and grease.

Biochemical oxygen demand (BOD), which is a gross measurement of a range of organic pollutants, may be used to gauge the effectiveness of a biological wastewater treatment system, and is used as a regulatory parameter in some discharge permits.

The pollutants discharged vary by product sector and individual plant, and may include arsenic, chlorine, cyanide, fluoride; and heavy metals such as chromium, copper, iron, lead, mercury, nickel and zinc.

Many of these plants discharge wastewater with significant levels of metals such as lead, mercury, cadmium and chromium, as well as arsenic, selenium and nitrogen compounds (nitrates and nitrites).

[18] Technological advancements in ion-exchange membranes and electrodialysis systems has enabled high efficiency treatment of flue-gas desulfurization wastewater to meet recent EPA discharge limits.

[citation needed] Wastewater generated from agricultural and food processing operations has distinctive characteristics that set it apart from common municipal wastewater managed by public or private sewage treatment plants throughout the world: it is biodegradable and non-toxic, but has high Biological Oxygen Demand (BOD) and suspended solids (SS).

[citation needed] Processing of food from raw materials requires large volumes of high grade water.

Some municipalities require restaurants and food processing businesses to use grease interceptors and regulate the disposal of FOG in the sewer system.

Many food processing facilities require on-site treatment before operational wastewater can be land applied or discharged to a waterway or a sewer system.

High suspended solids levels of organic particles increase BOD and can result in significant sewer surcharge fees.

Sedimentation, wedge wire screening, or rotating belt filtration (microscreening) are commonly used methods to reduce suspended organic solids loading prior to discharge.

The wastewater discharged by glass plants may include ammonia, BOD, chemical oxygen demand (COD), fluoride, lead, oil, phenol, and/or phosphorus.

Contamination of waste streams includes gasification products such as benzene, naphthalene, anthracene, cyanide, ammonia, phenols, cresols together with a range of more complex organic compounds known collectively as polycyclic aromatic hydrocarbons (PAH).

[26] The conversion of iron or steel into sheet, wire or rods requires hot and cold mechanical transformation stages frequently employing water as a lubricant and coolant.

Typical processes conducted at these plants include grinding, machining, coating and painting, chemical etching and milling, solvent degreasing, electroplating and anodizing.

[30] Wastewater from metal mines and ore recovery plants are inevitably contaminated by the minerals present in the native rock formations.

Extraction of high value metals such as gold and silver may generate slimes containing very fine particles in where physical removal of contaminants becomes particularly difficult.

Pollutants generated by the industry include acetone, ammonia, benzene, BOD, chloroform, cyanide, ethanol, ethyl acetate, isopropanol, methylene chloride, methanol, phenol and toluene.

Plants that bleach wood pulp for paper making may generate chloroform, dioxins (including 2,3,7,8-TCDD), furans, phenols and chemical oxygen demand (COD).

[36] Stand-alone paper mills using imported pulp may only require simple primary treatment, such as sedimentation or dissolved air flotation.

Following treatment with polymer-based flocculants and settling agents, typical monitoring parameters include BOD, COD, color (ADMI), sulfide, oil and grease, phenol, TSS and heavy metals (chromium, zinc, lead, copper).

Industrial applications where oil enters the wastewater stream may include vehicle wash bays, workshops, fuel storage depots, transport hubs and power generation.

Wood preserving plants generate conventional and toxic pollutants, including arsenic, COD, copper, chromium, abnormally high or low pH, phenols, suspended solids, oil and grease.

Wastewater from industrial food processing often requires on-site treatment before it can be discharged to prevent or reduce sewer surcharge fees.

Some common ways to reduce solids include primary sedimentation (clarification), dissolved air flotation (DAF), belt filtration (microscreening), and drum screening.

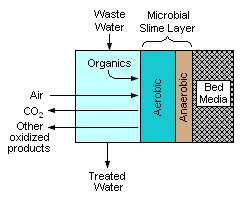

[56][57][58][59] Biodegradable organic material of plant or animal origin is usually possible to treat using extended conventional sewage treatment processes such as activated sludge or trickling filter.

[1][60] Problems can arise if the wastewater is excessively diluted with washing water or is highly concentrated such as undiluted blood or milk.

Methods include advanced oxidation processing, distillation, adsorption, ozonation, vitrification, incineration, chemical immobilisation or landfill disposal.

Target 6.3 of this goal is to "By 2030, improve water quality by reducing pollution, eliminating dumping and minimizing release of hazardous chemicals and materials, halving the proportion of untreated wastewater and substantially increasing recycling and safe reuse globally".