Dissolved air flotation

[1][2][3] Dissolved air flotation is very widely used in treating the industrial wastewater effluents from oil refineries, petrochemical and chemical plants, natural gas processing plants, paper mills, general water treatment and similar industrial facilities.

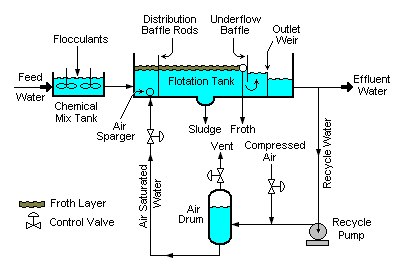

The air-saturated water stream is recycled to the front of the float tank and flows through a pressure reduction valve just as it enters the front of the float tank, which results in the air being released in the form of tiny bubbles.

This causes the suspended matter to float to the surface where it forms a froth layer which is then removed by a skimmer.

The froth-free water exits the float tank as the clarified effluent from the DAF unit.

The floating floc blanket is removed from the surface and clarified water is withdrawn from the bottom of the DAF tank.

Picture shows a 225 m 3 /h DAF.