Integral fast reactor

With the election of President Bill Clinton in 1992, and the appointment of Hazel O'Leary as the Secretary of Energy, there was pressure from the top to cancel the IFR.

The British journal Nature entitled its article "Report backs whistleblower", and also noted conflicts of interest on the part of a DOE panel that assessed IFR research.

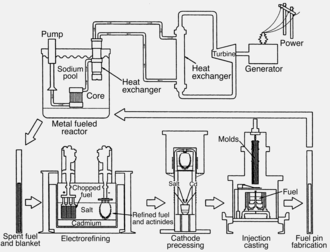

[12] Reprocessing is essential to achieve most of the benefits of a fast reactor, improving fuel usage and reducing radioactive waste by several orders of magnitude.

The uranium and transuranium elements are recycled into new fuel rods, and the fission products are eventually converted to glass and metal blocks for safer disposal.

Because the combined transuranium elements and the fission products are highly radioactive, fuel-rod transfer and reprocessing operations use robotic or remote-controlled equipment.

In contrast, since the IFR is a liquid metal cooled reactor, the core could operate at close to ambient pressure, dramatically reducing the danger of a loss-of-coolant accident.

The fuel and cladding are designed such that when they expand due to increased temperatures, more neutrons would be able to escape the core, thus reducing the rate of the fission chain reaction.

Most LWRs also have negative reactivity coefficients; however, in an IFR, this effect is strong enough to stop the reactor from reaching core damage without external action from operators or safety systems.

Pete Planchon, the engineer who conducted the tests for an international audience, quipped "Back in 1986, we actually gave a small [20 MWe] prototype advanced fast reactor a couple of chances to melt down.

The purpose of this loop is to ensure that any explosion following the accidental mixing of sodium and turbine water would be limited to the secondary heat exchanger and not pose a risk to the reactor itself.

The disadvantages of lead are its higher density and viscosity, which increases pumping costs, and radioactive activation products resulting from neutron absorption.

The goals of the IFR project were to increase the efficiency of uranium usage by breeding plutonium and to eliminate the need for transuranic isotopes to ever leave the site.

[15] The basic scheme uses pyroelectric separation, a common method in other metallurgical processes, to remove transuranics and actinides from the wastes and concentrate them.

The available fuel metals are never separated from the plutonium isotopes nor from all the fission products,[13][better source needed] and are therefore relatively difficult to use in nuclear weapons.

[note 1] In fact, in the U.S. most spent LWR fuel has remained in storage at the reactor site instead of being transported for reprocessing or placement in a geological repository.

The smaller volumes of high level waste from reprocessing could stay at reactor sites for some time, but are intensely radioactive from medium-lived fission products (MLFPs) and need to be stored securely, like in dry cask storage vessels.

[22] Also, despite the million-fold reduction in radiotoxicity offered by this scheme,[note 2] there remain concerns about radioactive longevity:[Some believe] that actinide removal would offer few if any significant advantages for disposal in a geologic repository because some of the fission product [sic] nuclides of greatest concern in scenarios such as groundwater leaching actually have longer half-lives than the radioactive actinides.

For example, the IFR's positive void coefficient could be reduced to an acceptable level by adding technetium to the core, helping destroy the long-lived fission product technetium-99 by nuclear transmutation in the process.

The limited literature that evaluates this potential future technology reports median life cycle GHG emissions... similar to or lower than LWRs [light water reactors] and purports to consume little or no uranium ore.No fission products have a half-lifein the range of 100 a–210 ka ... ... nor beyond 15.7 Ma[29] Fast reactor fuel must be at least 20% fissile, greater than the low-enriched uranium used in LWRs.

The fissile material can initially include highly enriched uranium or plutonium from LWR spent fuel, decommissioned nuclear weapons, or other sources.

The IFR fuel cycle's reprocessing by pyroprocessing (in this case, electrorefining) does not need to produce pure plutonium, free of fission product radioactivity, as the PUREX process is designed to do.

The purpose of reprocessing in the IFR fuel cycle is simply to reduce the level of those fission products that are neutron poisons; even these need not be completely removed.

Reprocessing nuclear fuel using pyroprocessing and electrorefining has not yet been demonstrated on a commercial scale, so investing in a large IFR-style plant may be a higher financial risk than a conventional LWR.

However, decay heat generation from short-lived fission products and actinides is comparable in both cases, starting at a high level and decreasing with time elapsed after shutdown.

The high volume of liquid sodium primary coolant in the pool configuration is designed to absorb decay heat without reaching fuel melting temperature.

Self-regulation of the IFR's power level depends mainly on thermal expansion of the fuel, which allows more neutrons to escape, damping the chain reaction.

However, the IFR's positive void coefficient could be reduced to an acceptable level by adding technetium to the core, helping destroy the long-lived fission product technetium-99 by nuclear transmutation in the process.

In addition to the passive shutdown of the reactor, the convection current generated in the primary coolant system will prevent fuel damage (core meltdown).

[13][better source needed] Rather than being transported from a large centralized reprocessing plant to reactors at other locations – as is common now in France, from La Hague to its dispersed nuclear fleet of LWRs – the IFR pyroprocessed fuel would be much more resistant to unauthorized diversion.

The sodium activation product (isotope) 24Na releases dangerous energetic photons when it decays (albeit having only short half-life of 15 hours).