International Harvester

The roots of International Harvester run to the 1830s, when Virginia inventor Cyrus Hall McCormick perfected his version of a horse-drawn reaper, which he field-demonstrated in 1831 and for which he received a patent in 1834.

IH next set their sights on introducing a true 'general-purpose' tractor to satisfy the needs of the average American family farmer.

[citation needed] IH ranked 33rd among United States corporations in the value of World War II production contracts.

IH faced strong competition and increased production costs, primarily due to labor and government-imposed environmental and safety regulations.

In 1977, International Harvester named Archie McCardell as its new CEO, who embarked on a strategy to drastically cut costs and improve profit margins.

On November 1, 1979, just as the company announced a $1.8 million bonus for McCardell, the United Auto Workers called a strike the following day.

[14] Menk also ensured that IH made necessary cutbacks, and it involved the sale of the company's Payline division of construction equipment to Dresser Industries.

Sold by McCormick dealers, the Type C Mogul was little more than a stationary engine on a tractor chassis, fitted with friction drive (one speed forward, one reverse).

Production of the Cub commenced at the newly acquired and updated Farmall Works-Louisville plant (formerly the wartime Curtiss-Wright Aircraft factory in Louisville, Kentucky).

Another option became available in 1965 for the 706, 806, and the new 1206: a factory-installed cab (made by Stopler Allen Co.), often called the "ice cream box" due to its shape.

The 966 and 1066 were available with Hydro or gearshift transmissions and the choice of two-post roll over protection structures (ROPs) or two different cabs, the "custom" and the "deluxe".

After a downturn in the market coupled to problems with Spain's entry into the European Economic Community threatened the profitability of this project, International Harvester withdrew in 1982.

IH over the years used a number of brand names to market their tractor and harvesting products: Along with its prominent tractor division, IH also sold several different types of farm-related equipment, such as balers, cultivators, combines (self-propelled and pull behind), stationary engines, wagons, combine heads, corn shellers, cotton pickers, manure spreaders, hay rakes, crop dusters, disk harrows, elevators, feed grinders, hammer mills, hay conditioners, milking machines, planters, mills, discs, plows, baler twine, and other miscellaneous equipment.

'[27] Rather than spend money on R&D and enter the market at a later date, in 1953 IH bought Heil's road machinery division, incorporating a range of motor and towed scrapers.

Amongst a variety of attachment solutions Bucyrus-Erie made a range of cable and hydraulically operated blades which fitted International-Harvester track type tractors.

One of the more novel applications of the Electrall was a device to electrocute insects in the field at night (basically like a modern-day bug zapper, but on a larger scale).

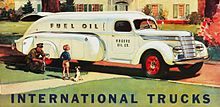

[33] IH is often remembered as a maker of relatively successful and innovative "light" lines of vehicles, competing directly against the Big Three.

[34] Powered by a horizontally opposed, air-cooled twin around 15 hp (11 kW), it was a right-hand-drive model popular in rural areas for high ground clearance on the poor roads typical of the era.

From 1983 to 2010, Ford Motor Company offered International V8 diesel engines in heavy-duty pickup trucks, vans, and SUVs (using the Power Stroke name after 1994).

Competing directly against the Ford C-Series, the Cargostar was a medium-duty truck fitted with a choice of gasoline or diesel engine (shared with the Loadstar conventional).

Developed as a Class 8 highway tractor, the Transtar 4200/4300 introduced an all-new cab that continued to be used for International heavy-duty trucks through 1999.

Competing against a wide range of manufacturers, the Transtar conventional was offered in both short and long-hood configurations for both regional and long-distance shipping.

Developed for severe-service use (primarily construction and related applications), the Paystar shared its cab with the Transtar, but used a heavier-duty chassis, steel fenders, and a flat-panel hood.

[40] The medium-duty Loadstar received an optional tilting hood with a larger grille and straighter-edge fenders (updating its appearance for the first time in 10 years).

[40] Competing against an extensive segment of the truck industry, the S-Series was produced in multiple layouts, hood lengths, and axle configurations; gasoline and diesel engines were offered.

As the company did not develop a tilt-cab truck derived from the S-series (or a distinct vehicle), International introduced the 400/500/700/900 low-cab COE, produced by Nissan Diesel (UD).

A variant with a midmounted, 20,000-lb winch, resulted in the first production model,[47] the Mk3 entering service in 1963 – just in time for Australia's entry into the Vietnam War.

A five-ton 6×6 version was to follow with three major variants the Truck Cargo 5 Ton with winch F1[48] which replaced the Mk3 in Vietnam service.

Engines used have been Cummins, Caterpillar, Detroit Diesel, Perkins, Neuss or GMC with Road-Ranger or Allison transmissions and Rockwell differentials.

The IH appliance division had originally been developed to manufacture commercial-grade items to farmers, most of whom had just received electricity by way of the many electrification projects in the U.S. before and after World War II.