Iron mining in the United States

[1] Iron ore was the third-highest-value metal mined in the United States, after gold and copper.

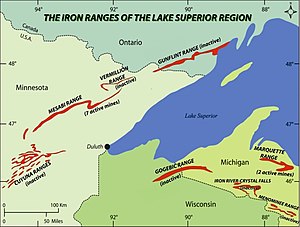

For the past 50 years, more than 90 percent of US iron ore production has been mined from the Lake Superior deposits.

Three of the mines are operated by Cleveland Cliffs, two by U.S. Steel, and one each by Mesabi Nugget Delaware LLC and Arcelor Mittal S.A.

In 2014, the two mines produced 12.1 million tons of pelletized iron ore concentrate.

The manufacturing of iron from ore likely began in 1622, in what is now Chesterfield County, Virginia, but was halted when American Indians killed everyone in the establishment.

[8] Iron production in the 1700s was done with charcoal, of which American forests could provide a seemingly endless supply.

[9] Although the bog iron ores mined in colonial days were widespread, the deposits were also small, and quickly exhausted.

Inland locations also allowed the furnaces to be closer to sources of limestone, which was used as a flux in iron smelting.

[11] New Jersey's principal iron ore district, at Randolph, began mining in 1710.

[12] Starting about 1820, coke from coal replaced charcoal as the fuel and reducing agent in iron furnaces.

Coke has a higher crushing strength than charcoal, allowing larger smelting furnaces.

Marie provided cheap water transportation between the iron mines to the lower Great Lakes.

Favorable locations for steelworks using Lake Superior ore included Great Lakes ports such as Chicago, Cleveland, and Gary, as well as cities close to coal and with good water transportation, such as Pittsburgh.