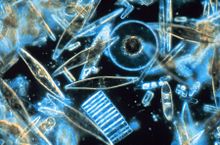

Diatomaceous earth

Diatomaceous earth (/ˌdaɪ.ətəˈmeɪʃəs/ DY-ə-tə-MAY-shəs), also known as diatomite (/daɪˈætəmaɪt/ dy-AT-ə-myte), celite, or kieselguhr, is a naturally occurring, soft, siliceous sedimentary rock that can be crumbled into a fine white to off-white powder.

The typical chemical composition of oven-dried diatomaceous earth is 80–90% silica, with 2–4% alumina (attributed mostly to clay minerals), and 0.5–2% iron oxide.

[2] Diatomaceous earth consists of the fossilized remains of diatoms, a type of hard-shelled microalgae, that have accumulated over millions of years.

[3] It is used as a filtration aid, mild abrasive in products including metal polishes and toothpaste, mechanical insecticide, absorbent for liquids, matting agent for coatings, reinforcing filler in plastics and rubber, anti-block in plastic films, porous support for chemical catalysts, cat litter, activator in coagulation studies, a stabilizing component of dynamite, a thermal insulator, and a soil for potted plants and trees as in the art of bonsai.

Many deposits throughout British Columbia, such as Red Lake Earth, are from the Miocene epoch and contain a species of diatom known as Melosira granulata.

There is a layer of diatomaceous earth more than 6 meters (20 ft) thick in the nature reserve of Soos in the Czech Republic.

Research has shown that the erosion of diatomaceous earth in such areas (such as the Bodélé Depression in the Sahara) is one of the most important sources of climate-affecting dust in the atmosphere.

Muck from several locations in Lake County, Florida was dried and burned (calcined) to produce the diatomaceous earth.

[20] Diatomaceous earth is available commercially in several formats: In 1866, Alfred Nobel discovered that nitroglycerin could be made much more stable if absorbed in diatomite (kieselguhr in German).

Diatom shells will work to some degree on the vast majority of animals that undergo ecdysis in shedding cuticle, such as arthropods or nematodes.

[28][29] It is commonly used in lieu of boric acid and can be used to help control and possibly eliminate bed bugs,[30] house dust mite, cockroach, ant, and flea infestations.

In order to be effective as an insecticide, diatomaceous earth must be uncalcinated (i.e., it must not be heat-treated prior to application)[33][better source needed] and have a mean particle size below about 12 μm (i.e., food grade—see below).

[citation needed] Although considered to be relatively low-risk, pesticides containing diatomaceous earth are not exempt from regulation in the United States under the Federal Insecticide, Fungicide, and Rodenticide Act and must be registered with the Environmental Protection Agency.

In vegetable gardening it is sometimes used as a soil conditioner, because like perlite, vermiculite, and expanded clay, it retains water and nutrients, while draining fast and freely, allowing high oxygen circulation within the growing medium.

Natural dried, not calcinated diatomaceous earth is regularly used in livestock nutrition research as a source of acid-insoluble ash (AIA), which is used as an indigestible marker.

By measuring the content of AIA relative to nutrients in test diets and feces or digesta sampled from the terminal ileum (last third of the small intestine) the percentage of that nutrient digested can be calculated using the following equation: where: Natural freshwater diatomaceous earth is preferred by many researchers over chromic oxide, which has been widely used for the same purpose, the latter being a known carcinogen and, therefore, a potential hazard to research personnel.

Spent diatomaceous earth from the brewing process can be added to ceramic mass for the production of red bricks with higher open porosity.

In particular there are bath mats made of DE which absorb water from the bather and allow it to spread the material and rapidly evaporate away.

Certain species of bacteria in oceans and lakes can accelerate the rate of dissolution of silica in dead and living diatoms by using hydrolytic enzymes to break down the organic algal material.

[49] The crystalline silica content of diatomaceous earth is regulated in the United States by the Occupational Safety and Health Administration (OSHA).

There are guidelines from the National Institute for Occupational Safety and Health that set maximum amounts allowable in the product (1%) and in the air near the breathing zone of workers, with a recommended exposure limit at 6 mg/m3 over an 8-hour workday.

[50] In the 1930s, long-term occupational exposure among workers in the cristobalite diatomaceous earth industry who were exposed to high levels of airborne crystalline silica over decades were found to have an increased risk of silicosis.

[51] Diatomite produced for pool filters is treated with high heat (calcination) and a fluxing agent (soda ash), causing the formerly harmless amorphous silicon dioxide to assume its crystalline form.