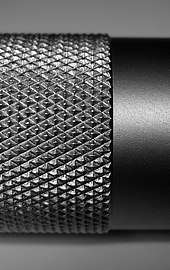

Knurling

Knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material.

As auto parts have become less expensive, knurling has become less prevalent than it once was, and is specifically discouraged by the builders of performance engines.

Tool handles, mechanical pencils, the grips of pistols, barbell bars, the clamping surface of a motorcycle handlebar and the control knobs on electronic equipment are frequently knurled.

It is possible for a "straight" knurl (not criss-crossed) to be pressed with a single roller, however the material needs to be supported adequately to avoid deformation.

Picking the correct stock diameter is very similar to having two gears of the same diametrical pitch that fit together.

[6][7] The integer number of knurls for any given diameter typically varies by three repetitions from the bottom to the top of the pattern.