Piston

In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder.

According to purpose, supercharging level and working conditions of engines the shape and proportions can be changed.

The pin itself is of hardened steel and is fixed in the piston, but free to move in the connecting rod.

These are a number of narrow iron rings, fitted loosely into grooves in the piston, just below the crown.

The rings are split at a point in the rim, allowing them to press against the cylinder with a light spring pressure.

Billet pistons are also used in racing engines because they do not rely on the size and architecture of available forgings, allowing for last-minute design changes.

Although not commonly visible to the naked eye, pistons themselves are designed with a certain level of ovality and profile taper, meaning they are not perfectly round, and their diameter is larger near the bottom of the skirt than at the crown.

[2] Early pistons were of cast iron, but there were obvious benefits for engine balancing if a lighter alloy could be used.

It runs within a small cylinder as a trunk guide and also carries the gudgeon pin.

The sides of the piston skirt around the gudgeon pin are reduced away from the cylinder wall.

The purpose is mostly to reduce the reciprocating mass, thus making it easier to balance the engine and so permit high speeds.

[5] Reduced inertia also improves mechanical efficiency of the engine: the forces required to accelerate and decelerate the reciprocating parts cause more piston friction with the cylinder wall than the fluid pressure on the piston head.

However, most friction is due to the piston rings, which are the parts which actually fit the tightest in the bore and the bearing surfaces of the wrist pin, and thus the benefit is reduced.

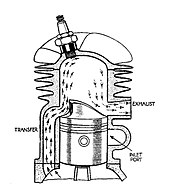

Media related to Slipper pistons at Wikimedia Commons Deflector pistons are used in two-stroke engines with crankcase compression, where the gas flow within the cylinder must be carefully directed in order to provide efficient scavenging.

To prevent the incoming mixture passing straight across from one port to the other, the piston has a raised rib on its crown.

The crowns developed from a simple rib to a large asymmetric bulge, usually with a steep face on the inlet side and a gentle curve on the exhaust.

Consequently, steam engine pistons are nearly always comparatively thin discs: their diameter is several times their thickness.