Landfill gas utilization

After fossil fuel and agriculture, landfill gas is the third largest human generated source of methane.

It is important not only to control its emission but, where conditions allow, use it to generate energy, thus offsetting the contribution of two major sources of greenhouse gases towards climate change.

These projects are popular because they control energy costs and reduce greenhouse gas emissions.

Methane (CH4) is the important component of landfill gas as it has a calorific value of 33.95 MJ/Nm^3 which gives rise to energy generation benefits.

The landfill gas production rate will reach a maximum at around 5 years and start to decline.

[8] Depending on the composition of the waste in place, there are many other minor components that comprises roughly 1% which includes H2S, NOx, SO2, CO, non-methane volatile organic compounds (NMVOCs), polycyclic aromatic hydrocarbons (PAHs), polychlorinated dibenzodioxins (PCDDs), polychlorinated dibenzofurans (PCDFs), etc.

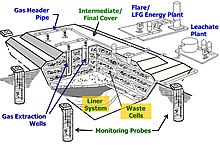

[5] Landfill gas collection is typically accomplished through the installation of wells – vertically and/or horizontally – in the waste mass.

Landfill gas is extracted and piped to a main collection header, where it is sent to be treated or flared.

A 40-acre (160,000 m2) landfill gas collection system with a flare designed for a 600 ft3/min extraction rate is estimated to cost $991,000 (approximately $24,000 per acre) with annual operation and maintenance costs of $166,000 per year at $2,250 per well, $4,500 per flare and $44,500 per year to operate the blower (2008).

In the U.K. and EU enclosed flares, from which the flame is not visible are mandatory at modern landfill sites.

Flares can be either open or enclosed, but the latter are typically more expensive as they provide high combustion temperatures and specific residence times as well as limit noise and light pollution.

Higher combustion temperatures and residence times destroy unwanted constituents such as un-burnt hydrocarbons.

General accepted values are an exhaust gas temperature of 1000 °C with a retention time of 0.3 seconds which is said to result in greater than 98% destruction efficiency.

The combustion temperature is an important controlling factor as if greater than 1100 °C, there is a danger of the exponential formation of thermal NOx.

Secondary treatment systems employ multiple cleanup processes, physical and chemical, depending on the specifications of the end use.

Two constituents that may need to be removed are siloxanes and sulfur compounds, which are damaging to equipment and significantly increase maintenance cost.

For boilers, about 8,000 to 10,000 pounds per hour of steam can be generated for every 1 million metric tons of waste-in-place at the landfill.

A microturbine would be needed to provide power in low gas extraction rate situations.

CNG and LNG can be used on site to power hauling trucks or equipment or sold commercially.

Three commonly used methods to extract the carbon dioxide from the gas are membrane separation, molecular sieve, and amine scrubbing.

The high-Btu processing equipment can be expected to cost $2,600 to $4,300 per standard cubic foot per minute (scfm) of landfill gas.

[9] Costs depend on quality of the end product gas as well as the size of the project.

The CNG project at Puente Hills Landfill in Los Angeles has realized $1.40 per gallon of gasoline equivalent with the flow rate of 250 scfm.

Gas turbines have relatively low maintenance costs and nitrogen oxide emissions when compared to RP engines.

Hydrogen used in fuel cells have zero emissions, high efficiency, and low maintenance costs.

Landfill gas projects also decrease local pollution, and create jobs, revenues and cost savings.

These totals amount to roughly 17,500,000 acres (7,100,000 ha) of pine or fir forests or annual emissions from 14,000,000 passenger vehicles.