Clinker (boat building)

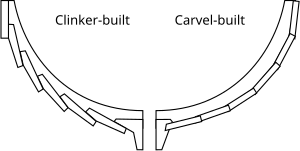

Clinker-built, also known as lapstrake-built,[1][2] is a method of boat building in which the edges of longitudinal (lengthwise-running) hull planks overlap each other.

][not verified in body] It was also used in cogs, the other major ship construction type found in Northern Europe in the latter part of the medieval period.

These fastenings typically go through a metal rove over which the protruding end of the nail is deformed in a process comparable to riveting the planks together.

The construction sequence begins with the joining of the keel, stem and sternpost (or transom) and setting these in place in the build area.

However, this timber conversion method does limit the maximum width of plank to slightly more than one third of the diameter of the tree from which it is split – the narrowest part (including any pith) and the sapwood are cut off.

[5]: 53–54, 60 [9] The slightly uneven surface found on cleft timber is the reason why caulking is laid in the overlap between the hull planks during construction, often using animal hair.

][citation needed] Modern examples of clinker-built boats that are directly descended from those of the early medieval period are seen in the traditional round-bottomed Thames skiffs, the larger (originally) cargo-carrying Norfolk wherries of England,[10] and working craft like the yawls that were once common around the coasts of Britain and Ireland.

In the Roman-occupied parts of Northern Europe, the Romano-Celtic tradition involved flush-planking that was not joined with mortise and tenon joints but was connected by framing elements.

The archaeological remains of a river boat dated to the first two centuries AD (described as Romano-Celtic), found in Pommeroeul in Belgium, had a single strake that overlapped the underlying plank – though it is not clear how it was fastened.

[13]: 201, 207–210 [5]: 63-66 The earliest example of ship and boat building using overlapped planking joined with metal fastenings is in an extended logboat from Björke in Sweden.

[5]: 63-66 [13]: 210-211 Though clinker construction is closely associated with Nordic countries, the same technique was used at an early stage in other parts of Northern Europe.

Other sites from the 7th century AD include Kvalsund, Norway, Gretstedbro in Jutland and Snape in eastern England.

This suggests that large oak trees for ship-building had become a lot less common by the 7th century, so timber of smaller dimensions had to be used.

[13]: 212-217 The cog is part of another ship-building tradition in Northern Europe that existed at the same time that the purely Nordic-tradition clinker vessels were being built.

[d] By the end of the 13th century AD, Mediterranean ships were being built on a skeleton basis, with hull planks being fixed to the frames and not to each other.

The visiting cogs had a single square-rigged mast, a stern-post mounted pintle-and-gudgeon rudder and clinker sides.

As part of the process of merging these two sets of traditions, carvel-built ships started to arrive in Northern waters.

The frames of carvel could be made stronger to support the weight of the guns that ships were starting to carry and allowed gun-ports to be cut in the hull.

Carvel construction may have solved the shortage of large cleft oak planks from which to make larger clinker vessels.

Once the shell of planking is assembled, transverse battens of oak, ash, or elm, called timbers, are steam-bent to fit the internal, concave side.

Bilge keels are often added to the outside of the land on which the boat would lie on a hard surface to stiffen it and protect it from wear.

In a sailing dinghy, there would be more fittings, such as fairleads, horse, shroud plates, mast step, toe straps and so on.

[citation needed] In the last few years of wooden boat construction, glue and screws took over, but until the 1950s, the keel, hog, stem, apron, deadwoods, sternpost, and perhaps transom would be fastened together by bolts set in white lead and grease.

[citation needed] Until the late 1950s, the centre-line assembly of British Admiralty twenty-five foot motor cutters were fastened in this way.

[citation needed] The Vikings used the clinker form of construction to build their longships from split wood planks.

This distribution of relative efficiency between the two forms of construction is an illusion because for given hull strength, the clinker boat is lighter.