Lay-up process

Dry Lay-up is a common process in the aerospace industry, due to the possibility of obtaining complex shapes with good mechanical properties, characteristics required in this field.

On the contrary, as Wet Lay-Up does not allow uni-directional fabrics, which have better mechanical properties, it is mainly adopted for all other areas, which in general have lower requirements in terms of performance.

More automatized alternatives are die-cutting systems, which allow higher production rates to be reached while limiting overall costs, as they allow more layers of fabric to be cut simultaneously.

[citation needed] These methods require different skills from the operator and provide different finish precisions, but they all are mechanical procedures and have one major disadvantage in common: the physical contact between the cutting tool and the fibres.

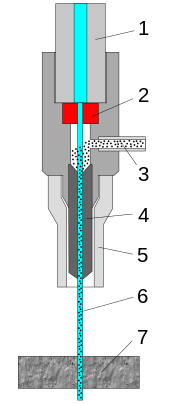

[4] An alternative process with less friction is the ultrasound method, which consists of cutting the fabrics with a blade actuated by high-frequency mechanical vibrations, produced by an internal source integrated into the system.

The latter is based on a high-pressure liquid beam which reaches a velocity of 2.5 times the speed of sound, creating a pressure on the fabric which is higher than the compression resistance of the material and resulting in a net cut.

[citation needed] Peel-plies are nylon films used to obtain a specific roughness of the surface on which they are applied, to protect them during storage and to trap volatile particles during polymerization.

[citation needed] Usually, intermediate compacting is performed every 4 or 5 layers, in order to let the air evacuate and to obtain a final product with better mechanical characteristics.

An alternative is a semi-automatic - also called "mechanically assisted" - process, consisting of a machine which handles the layers, which are then applied on the mould by an operator.

The advantage is due to the fact that the pressure helps to bond the composite layers and to eject air inclusions and volatile products, increasing the quality of the process.

It is made of a press with male and female moulds that close to form a gap with the shape of the component, the width of which is regulated to control the thickness of the part.

[1][8][12] As Meola et al. pointed out in Infrared thermography in the evaluation of aerospace composite materials, "Several different types of defects may occur during the fabrication of composites, the most common being fibre/play misalignment, broken fibres, resin cracks or transversal ply cracks, voids, porosity, slag inclusions, nonuniform fibre/resin volume ratio, disbonded interlaminar regions, kissing bonds, incorrect cure and mechanical damage around machined holes and/or cuts.