Light switch

The first light switch employing "quick-break technology" was invented by John Henry Holmes in 1884 in the Shieldfield district of Newcastle upon Tyne.

Arcing would cause pitting on one contact and the build-up of residue on the other, and the switch's useful life would be diminished.

Holmes' invention ensured that the contacts would separate or come together very quickly, however much or little pressure was exerted by the user on the switch actuator.

The action of this "quick break" mechanism meant that there was insufficient time for an arc to form, and the switch would thus have a long working life.

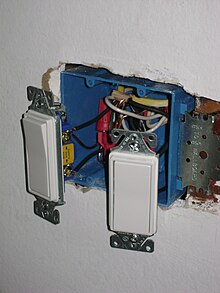

In different countries the standard dimensions of the wall mounting hardware (boxes, plates, etc.)

Since the face-plates used must cover this hardware, these standards determine the minimum sizes of all wall mounted equipment.

The dimensions, mechanical designs, and even the general appearance of light switches have changed slowly over time.

Switches typically remain in service for many decades, often being changed only when a portion of a house is rewired.

Manufacturers introduce various new forms and styles, but for the most part decoration and fashion concerns are limited to the face-plates or wall-plates.

In North American site-built and mobile homes, often living rooms and bedrooms have a switched receptacle for a floor or table lamp.

[2] The switch actuator does not control the contacts directly, but through an intermediate arrangement of springs and levers.

Turning the actuator does not initially cause any motion of the contacts, which in fact continue to be positively held open by the force of the spring.

However, if they control only compact fluorescent lamps (CFLs) and/or LED lamps, the small amount of current required to energize the lighting source within switch also slowly charges the internal input capacitor in the electronic ballast of the CFL or LED until the voltage across it rises to the point where it produces a brief discharge through the CFL.

Large switches of this design are commonly known in the United States as "decorator" or "Decora" style.

Switches of this design sit almost flush with the wall plate, and are activated by "rocking" a flat, broad lever, rather than pushing a short protruding actuator up or down.

In Europe, Brazil,[7] Hong Kong, Malaysia, Singapore, and India this type is near-universal, and toggle style switches would be considered old-fashioned.

A slightly larger "cover plate", supplied with the wall-plate, or additional to it, then clips over the assembly, as an additional insulating barrier covering the deep set wall-plate mounting screws - which are "deep set" to prevent inadvertent human contact.

Although the switches had adequate ratings for usage on 120 V circuits and had advantages of compactness and distinctive appearance, they failed to establish themselves in the American market.

One form of mercury light switch uses a sealed glass vial that is tipped by the toggle lever, causing a drop of liquid metallic mercury to roll from one end to the other, bridging a pair of contacts to complete the circuit.

[12] Some of these switches were also equipped with a neon lamp connected across the contacts, and thus in series with the electrical load.

It is also possible to have the cord-operated switch separate from the light socket, which is particularly common in British bathrooms.

Until 2001, UK wiring regulations required that all bathroom switches were operated by pull cords.

There are also more sophisticated cord mounted switches, like multiple switching (for lamps with more than one bulb, or fans with more speeds, in this case they have one input and 2 or more outputs), variators and dimmers (light dimmers, electric pillows and mattresses or some fans with more speeds).

In principle, it is easy to design silent switches in which the mechanical contacts do not directly control the current but simply signal a solid-state device such as a thyristor to complete the circuit.

Public buildings such as hospitals frequently save energy by using motion detector switches, also known as occupancy sensors.

In some cases, especially in hospitals and other public facilities, exposed parts of light switches are made of antimicrobial materials such as copper, for infection control.