Lignosulfonates

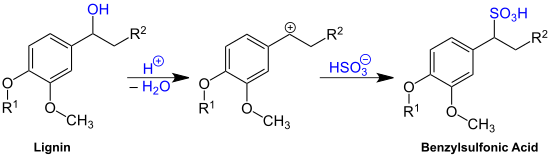

[1] Most delignification in sulfite pulping involves acidic cleavage of ether bonds, which connect many of the constituents of lignin.

A range of further modifications may be applied to LS and SL, including oxidation, hydroxymethylation, sulfomethylation, and a combination thereof.

[4] The electrophilic carbocations produced during ether cleavage react with bisulfite ions (HSO3−) to give sulfonates.

They are used to stably disperse pesticides, dyes, carbon black, and other insoluble solids and liquids into water.

Lignosulfonates are also used for the production of plasterboard to reduce the amount of water required to make the stucco flow and form the layer between two sheets of paper.

The reduction in water content allows lower kiln temperatures to dry the plasterboard, saving energy.

The ability of lignosulfonates to reduce the viscosity of mineral slurries (deflocculation) is used to advantage in oil drilling mud, where it replaced tannic acids from quebracho (a tropical tree).

They are used as binders in well-paper, particle boards, linoleum flooring, coal briquettes, and roads.

They also form a constituent of the paste used to coat the lead-antimony-calcium or lead-antimony-selenium grids in a Lead-acid battery.

Aqueous lignosulfonate solutions are also widely used as a non-toxic dust suppression agent for unpaved road surfaces, where it is popularly, if erroneously, called "tree sap".