Lithium polymer battery

The primary difference is that instead of using a liquid lithium-salt electrolyte (such as lithium hexafluorophosphate, LiPF6) held in an organic solvent (such as EC/DMC/DEC), the battery uses a solid polymer electrolyte (SPE) such as polyethylene glycol (PEG), polyacrylonitrile (PAN), poly(methyl methacrylate) (PMMA) or poly(vinylidene fluoride) (PVdF).

The dry SPE was the first used in prototype batteries, around 1978 by Michel Armand,[4][5] and 1985 by ANVAR and Elf Aquitaine of France, and Hydro-Québec of Canada.

[6] Since 1990, several organisations, such as Mead and Valence in the United States and GS Yuasa in Japan, have developed batteries using gelled SPEs.

The exact voltage ratings should be specified in product data sheets, with the understanding that the cells should be protected by an electronic circuit that won't allow them to overcharge or over-discharge under use.

[11] LiPo batteries are now almost ubiquitous when used to power commercial and hobby drones (unmanned aerial vehicles), radio-controlled aircraft, radio-controlled cars, and large-scale model trains, where the advantages of lower weight and increased capacity and power delivery justify the price.

LiPo batteries are pervasive in mobile devices, power banks, very thin laptop computers, portable media players, wireless controllers for video game consoles, wireless PC peripherals, electronic cigarettes, and other applications where small form factors are sought.

They offer numerous benefits over the traditional VRLA battery, and with stability and safety improvements confidence in the technology is growing.

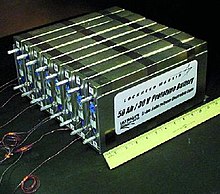

Their power-to-size and weight ratio is seen as a major benefit in many industries requiring critical power backup, including data centers where space is often at a premium.

All Li-ion cells expand at high levels of state of charge (SOC) or overcharge due to slight vaporisation of the electrolyte.

This may result in delamination and, thus, bad contact with the internal layers of the cell, which in turn diminishes the reliability and overall cycle life.

[9] This is very noticeable for LiPos, which can visibly inflate due to the lack of a hard case to contain their expansion.

To improve the ionic conductivity at room temperature, gelled electrolyte is added resulting in the formation of GPEs.

[18] The conduction mechanism is similar for liquid electrolytes and polymer gels, but GPEs have higher thermal stability and a low volatile nature which also further contribute to safety.

[23] The simplest approach is to use a polymer matrix, such as polyvinylidene fluoride (PVdF) or poly(acrylonitrile) (PAN), gelled with conventional salts and solvents, such as LiPF6 in EC/DMC/DEC.

PEO exhibits the most promising performance as a solid solvent for lithium salts, mainly due to its flexible ethylene oxide segments and other oxygen atoms that comprise a strong donor character, readily solvating Li+ cations.

[17] The performance of these proposed electrolytes is usually measured in a half-cell configuration against an electrode of metallic lithium, making the system a "lithium-metal" cell.