Lockheed Martin X-33

The X-33 would flight-test a range of technologies that NASA believed it needed for single-stage-to-orbit reusable launch vehicles (SSTO RLVs), such as metallic thermal protection systems, composite cryogenic fuel tanks for liquid hydrogen, the aerospike engine, autonomous (uncrewed) flight control, rapid flight turn-around times through streamlined operations, and its lifting body aerodynamics.

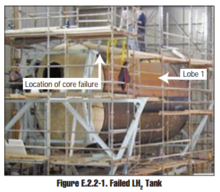

[3] Failures of its 21-meter wingspan and multi-lobed, composite-material fuel tank during pressure testing ultimately led to the withdrawal of federal support for the program in early 2001.

[5] .. to build a vehicle that takes days, not months, to turn around; dozens, not thousands, of people to operate; with launch costs that are a tenth of what they are now.

[6] Construction of the prototype was some 85% assembled with 96% of the parts and the launch facility 100%[7] complete when the program was canceled by NASA in 2001, after a long series of technical difficulties including flight instability and excess weight.

[citation needed] In 2004 Northrop Grumman successfully built and tested a simple cylindrical composite cryogenic hydrogen tank as part of early work for the Constellation program.

[9] Through the use of the lifting body shape, composite multi-lobed liquid fuel tanks, and the aerospike engine, NASA and Lockheed Martin hoped to test fly a craft that would demonstrate the viability of a single-stage-to-orbit (SSTO) design.

The uncrewed craft would have been launched vertically from a specially designed facility constructed on Edwards Air Force Base,[7] and landed horizontally (VTHL) on a runway at the end of its mission.

Initial sub-orbital test flights were planned from Edwards AFB to Dugway Proving Grounds southwest of Salt Lake City, Utah.

[citation needed] On July 2, 1996, NASA selected Lockheed Martin Skunk Works of Palmdale, California, to design, build, and test the X-33 experimental vehicle for the RLV program.

Based on the X-33 experience shared with NASA, Lockheed Martin hoped to make the business case for a full-scale SSTO RLV, called VentureStar, that would be developed and operated through commercial means.

[18]: 49 McDonnell Douglas featured a design using liquid oxygen/hydrogen bell engines based on its vertical takeoff and landing DC-XA test vehicle.