Machine to machine

to application software that can use it (for example, adjusting an industrial process based on temperature or placing orders to replenish inventory).

[3] Such communication was originally accomplished by having a remote network of machines relay information back to a central hub for analysis, which would then be rerouted into a system like a personal computer.

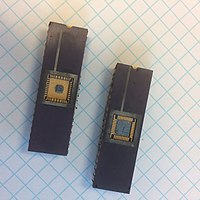

His portable transmitter and receiver were reduced to practice in 1971 in a Boeing facility in Huntsville, Alabama, representing the world's first working prototypes of caller identification devices (shown at right).

He was also the first to introduce the concepts of intelligence, data processing and visual display screens into telephones which gave rise to the smartphone.

The cellular M2M communications industry emerged in 1995 when Siemens set up a department inside its mobile phones business unit to develop and launch a GSM data module called "M1"[9] based on the Siemens mobile phone S6 for M2M industrial applications, enabling machines to communicate over wireless networks.

The first M1 module was used for early point of sale (POS) terminals, in vehicle telematics, remote monitoring and tracking and tracing applications.

[11] Initially relying heavily on the Orbcomm network for its satellite communication services, Quake Global expanded its telecommunication product offerings by engaging both satellite and terrestrial networks, which gave Quake Global an edge in offering network-neutral[12] products.

[citation needed] In 2004, Christopher Lowery, a UK telecoms entrepreneur, founded Wyless Group, one of the first Mobile Virtual Network Operators (MVNO) in the M2M space.

[15] Also in 2009, Wyless Group introduced PORTHOS™, its multi-operator, multi-application, device agnostic Open Data Management Platform.

In the UK, Business MVNO Abica, commenced trials with Telehealth and Telecare applications which required secure data transit via Private APN and HSPA+/4G LTE connectivity with static IP address.

In June 2010, mobile messaging operator Tyntec announced the availability of its high-reliability SMS services for M2M applications.

In March 2011, machine to machine network service provider KORE Wireless teamed with Vodafone Group and Iridium Communications Inc., respectively, to make KORE Global Connect network services available via cellular and satellite connectivity in more than 180 countries, with a single point for billing, support, logistics and relationship management.

Later that year, KORE acquired Australia-based Mach Communications Pty Ltd. in response to increased M2M demand within Asia-Pacific markets.

In April 2013, OASIS MQTT standards group is formed with the goal of working on a lightweight publish/subscribe reliable messaging transport protocol suitable for communication in M2M/IoT contexts.

[31] Some companies, such as M-kopa in Kenya, are using M2M to enforce a payment plan, by turning off its customers' solar devices remotely for non-payment.

[32] "Our loan officer is that SIM card in the device that can shut it off remotely," says Chad Larson, M-Kopa's finance director and its third co-founder, when describing the technology.

Recent examples include Ford Motor Company, which has teamed with AT&T to wirelessly connect Ford Focus Electric with an embedded wireless connection and dedicated app that includes the ability for the owner to monitor and control vehicle charge settings, plan single- or multiple-stop journeys, locate charging stations, pre-heat or cool the car.

[35] In addition, with the help of highly interconnected machine networks and advance intelligent analysis tools, several novel maintenance types are made possible nowadays.

The Synchronization Module and Intelligent Tools comprise the major processing power of the e-maintenance machine network and provide optimization, prediction, clustering, classification, bench-marking and so on.

This method was introduced to address the challenge of developing fault detection models for applications with non-stationary operating regimes or with incomplete data.

Instead, by leveraging on data generated from other similar turbines in the network, this problem can be properly solved and local fault detection models can be effective built.

Industrial robots are crucial in automotive manufacturing and perform different tasks as welding, material handling, painting, etc.

Critical model parameters like training samples, components, and alarming limits are set the same for all the units regardless of their different functionalities.

However, within a machine network, industrial robots with similar tasks or working regimes can be group together; the abnormal units in a cluster can then be prioritized for maintenance via training based or instantaneous comparison.