Membrane fouling

There are various types of foulants: colloidal (clays, flocs), biological (bacteria, fungi), organic (oils, polyelectrolytes, humics) and scaling (mineral precipitates).

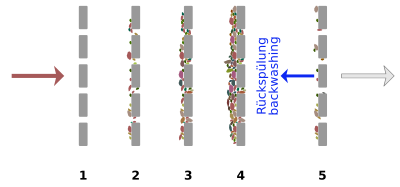

Physical cleaning includes gas scour, sponges, water jets or backflushing using permeate[10] or pressurized air.

A 2018 study from the Global Aqua Innovation Center in Japan reported improved surface roughness properties of PA membranes by coating them with multi-walled carbon nanotubes.

It is important to note that the majority of membranes used commercially are polymers such as polyvinylidene fluoride (PVDF), polyacrylonitrile (PAN), polyethersulfone (PES) and polyamide (PA), which are materials which offer desirable properties (elasticity and strength) to withstand constant osmotic pressures.

The accumulation of foulants can lead to the formation of cracks, surface roughening, and changes in pore size distribution.

[15] These physical changes are the result of impacts of hard material with a soft polymer membrane, weakening its structural integrity.

[16] Beyond direct physical damage, fouling can also induce indirect effects on membrane mechanical properties due to the strategies used to combat it.

This is a process whereby existing imperfections in the membrane (such as microcracks) can grow and propagate due to the complex stress state dynamics.

These impacts are not unknown; A 2007 study simulated aging via cyclic backwash pulses, and reported similar embrittlement due to the effects.