Neo-Hookean solid

A neo-Hookean solid[1][2] is a hyperelastic material model, similar to Hooke's law, that can be used for predicting the nonlinear stress–strain behavior of materials undergoing large deformations.

The model was proposed by Ronald Rivlin in 1948 using invariants, though Mooney had already described a version in stretch form in 1940, and Wall had noted the equivalence in shear with the Hooke model in 1942.

Instead, the relationship between applied stress and strain is initially linear, but at a certain point the stress–strain curve will plateau.

The neo-Hookean model does not account for the dissipative release of energy as heat while straining the material, and perfect elasticity is assumed at all stages of deformation.

In addition to being used to model physical materials, the stability and highly non-linear behaviour under compression has made neo-Hookean materials a popular choice for fictitious media approaches such as the third medium contact method.

The neo-Hookean model is based on the statistical thermodynamics of cross-linked polymer chains and is usable for plastics and rubber-like substances.

However, at a certain point the polymer chains will be stretched to the maximum point that the covalent cross links will allow, and this will cause a dramatic increase in the elastic modulus of the material.

The primary, and likely most widely employed, strain-energy function formulation is the Mooney-Rivlin model, which reduces to the widely known neo-Hookean model.

The strain energy density function for an incompressible Mooney—Rivlin material is Setting

reduces to the (incompressible) neo-Hookean strain energy function where

is the first principal invariant (trace), of the left Cauchy-Green deformation tensor, i.e., where

Note that this is one of several strain energy functions employed in hyperelasticity measurements.

term, namely The difference Cauchy stress tensors resulting from these two compressible strain energy functions is given in the proof section below, where the other strain energy function is called "Rivlin".

are sometimes used, notably in commercial finite element analysis software such as Abaqus.

[5] For a compressible Ogden neo-Hookean material the Cauchy stress is given by where

By simplifying the right hand side we arrive at which for infinitesimal strains is equal to Comparison with Hooke's law shows that

For a compressible Rivlin neo-Hookean material the Cauchy stress is given by where

is the left Cauchy–Green deformation tensor, and For infinitesimal strains (

) and the Cauchy stress can be expressed as Comparison with Hooke's law shows that

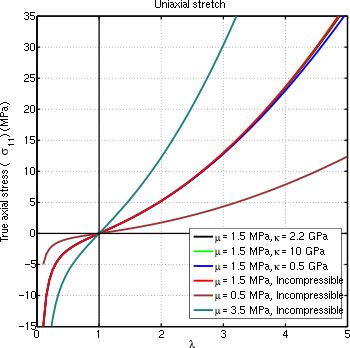

For a compressible neo-Hookean hyperelastic material, the principal components of the Cauchy stress are given by Therefore, the differences between the principal stresses are For a compressible hyperelastic material, the principal components of the Cauchy stress are given by The strain energy density function for a compressible neo Hookean material is Therefore, Since

we have Hence, The principal Cauchy stresses are therefore given by In terms of the principal stretches, the Cauchy stress differences for an incompressible hyperelastic material are given by For an incompressible neo-Hookean material, Therefore, which gives For a compressible material undergoing uniaxial extension, the principal stretches are Hence, the true (Cauchy) stresses for a compressible neo-Hookean material are given by The stress differences are given by If the material is unconstrained we have

, i.e., or The above equation can be solved numerically using a Newton–Raphson iterative root-finding procedure.

For the engineering stress the equation is: For small deformations

we will have: Thus, the equivalent Young's modulus of a neo-Hookean solid in uniaxial extension is

and the differences between the principal Cauchy stresses take the form Under plane stress conditions we have For the case of pure dilation Therefore, the principal Cauchy stresses for a compressible neo-Hookean material are given by If the material is incompressible then

The figures below show that extremely high stresses are needed to achieve large triaxial extensions or compressions.

Equivalently, relatively small triaxial stretch states can cause very high stresses to develop in a rubber-like material.

For the case of simple shear the deformation gradient in terms of components with respect to a reference basis is of the form[2] where

Therefore, the left Cauchy-Green deformation tensor is In this case

The expressions for the Cauchy stress for a compressible and an incompressible neo-Hookean material in simple shear represent the same quantity and provide a means of determining the unknown pressure